Over the past few years, we have featured a handful of Dodge Challenger SRT® Hellcat and Charger SRT Hellcat racers who have covered the quarter-mile in less than 8 seconds, but those cars have all had one thing in common. They were all heavily modified to make gobs more power, utilizing a larger aftermarket supercharger that jams more air into the hungry HEMI® engine. As you add more air, you can add more fuel and that leads to the kind of power needed to run a 7-second quarter-mile.

However, a few hardcore Dodge racers have stuck with the factory IHI supercharger and at the final Modern Street HEMI Shootout event of 2023, Jon Sipple piloted his Challenger SRT Hellcat into the 7-second quarter-mile club with the factory 2.4-liter blower. To make the run even more impressive, Sipple’s Challenger SRT Hellcat is also equipped with the factory ZF 8-speed automatic transmission, which is also a rarity among the modern Mopar® vehicles running quicker than 8.00. This makes Jon Sipple’s Go Mango Dodge Challenger SRT Hellcat the first to run in the 7-second range with the factory supercharger and transmission.

Upon hearing of this milestone, we reached out to Jon Sipple, who provided us with plenty of information on how he got his Challenger SRT Hellcat into the 7s with these key factory components – and a curb weight nearing 4,500 pounds.

“What a journey. I started the quest for 7s in January when the new build debuted in Texas at the Legion of Demons event,” said Jon. “Tim [Barth of Barth Tuning] and I had started track tuning the car there and got up to a 200 shot of nitrous oxide, which gave us an 8.27 at 169.00. We had a 350 shot loaded right when the rain came and ended the event.

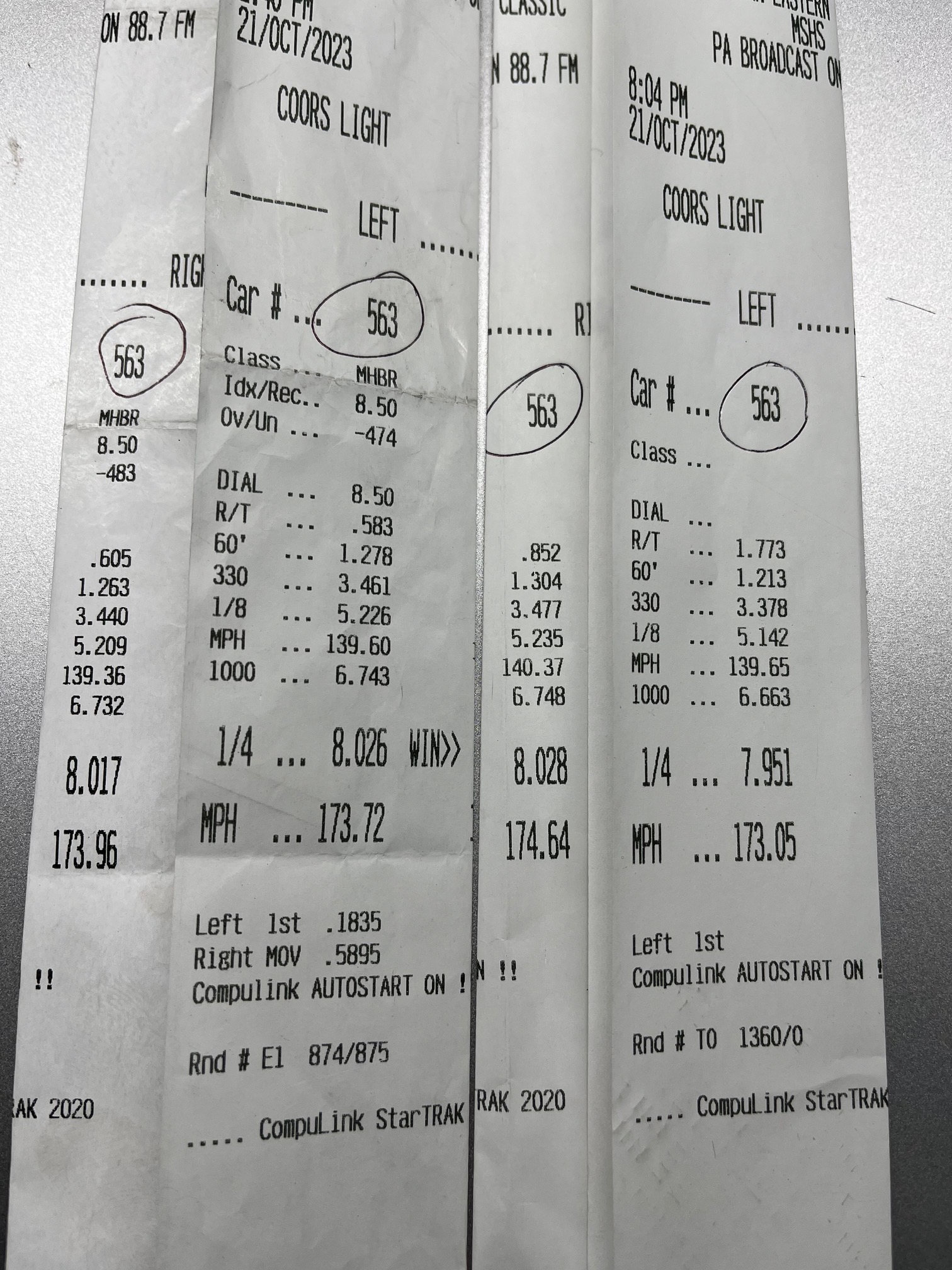

“I have made 200-plus passes in the car this season and being busy with the transmission shop, Tim and I rarely had time to be together at a track. We made time at Steele October 11th where we worked on the tune and got it to run 8.04 at 172.00. I broke the diff bushings, which broke the driveshaft and ended my day. I quickly fixed the car to make Maryland, where after a few more tweaks, I went 8.01 and 8.02 twice before finally getting the car to 60 feet where it needed to get the 7.95. Density altitude was 650 feet and I think it was 68 degrees out around 8pm when I got my 7.”

If you are involved in the modern Dodge racing community, you likely know of Jon Sipple. He has been racing SRT Hellcat cars since they hit the market, setting some of the earliest records for a manually shifted Challenger SRT Hellcat. He is also the man in charge at Sipple Speed and Performance (SSP), where he has built many of the strongest transmissions that you will find in an SRT Hellcat car. His shop does more than just build transmissions, but his gearbox builds are found in a great many modern Dodge racecars. As you might expect, the ZF 8-speed in his Go Mango SRT Hellcat Challenger was built to handle all of that power, showcasing the SSP Max Effort HP90 package and a Pro torque billet stator converter with proprietary stall speed. The transmission was built by Jordan Daughaday, the head builder at SSP.

“This car is a test mule for Sipple Speed and Performance transmissions. This particular event, we had Tim Holmberg’s Max Effort HP90 with an experimental trans brake in the car for testing. This transmission went straight from the bench to the car and right on to the track. We wanted to test the trans with the brake installed to see how it would act if run normally without using the transbrake and to torture test the unit without break in to see what would happen. Both tests passed with flying colors. The transbrake was being tested before sending the unit to Holmberg for installation into his Twin Turbo Demon,” said Jon.

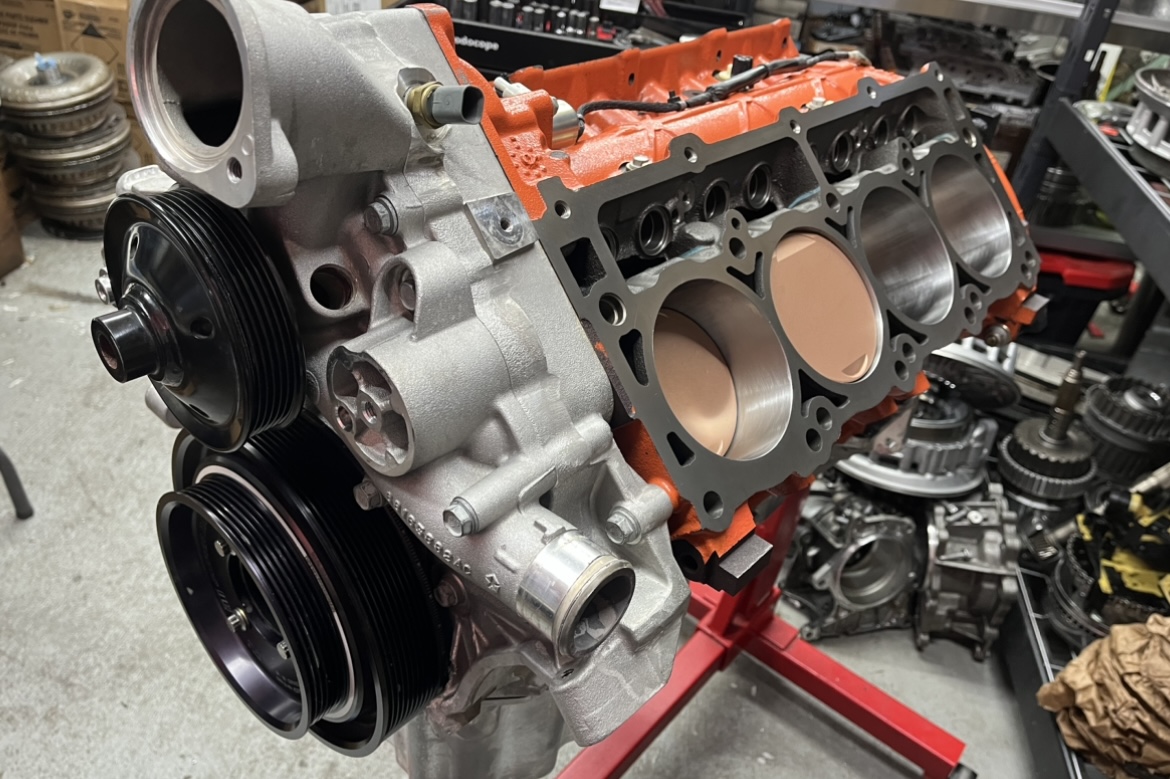

As for the powerplant, Sipple is running a 419-cubic-inch Gen III HEMI engine that is built around a factory SRT Hellcat HEMI engine block with a 4.100 bore, with the machining work and assembly handled by Gibbons Motorsports in Mooresville, North Carolina. This monstrous mill features a 3.975 Winberg billet crankshaft, Boostline I-beat connecting rods and CP coated pistons with plasma rings gapped for big boost and nitrous oxide, leading to a 12-to-1 compression ratio. The top end features Factory SRT Hellcat heads decked .030 and ported with PSI 1516 spring, Manton rocker shafts, ARP shaft bolts, Stanke Tie bars and collars, ARP head and main studs, Cometic SEG .051 head gaskets, a Cam Motion billet camshaft with Johnson short travel lifters and Manton push rods.

As for the supercharger, while it is a factory 2.4-liter IHI unit, it has been modified a bit as well. First, SDG Motorsports Trifecta package, featuring their “Hellephant killer” snout, their X-treme billet bearing plate and a Nick Williams 108mm throttle body. The supercharger also features a machined lid spacer, Nitrous Outlet spray bars and FI Interchiller spacers and blanket. A Griptech 2.65 pulley is mounted on the supercharger and an ATI 10% lower pulley is mounted on the engine, with a Gates 594 belt and a Barth idler keeping the system tight.

Sipple uses a two stage nitrous oxide system, with the bars in the blower providing a “300 shot” while a throttle body plate adds another 100 shot, both of which work with a dedicated fuel system. A Legmaker intake with a modified factory air box works with a modified radiator support to allow plenty of air to get to the engine while 2-inch Stainless Works headers with an x-pipe and turndowns allow the engine to exhale properly. The engine is tuned by Tim Barth to run on Ignite 90 with a Fore triple pump fuel system and FIC 2150 injectors, and the engine air intake temperature is kept low by an IC Chiller intercooler chiller system and a Gearhead Fabrications auxiliary tank.

Based on the weight and the times that he has run, Jon Sipple estimates that his Dodge Challenger SRT Hellcat is making north of 1,770 crank horsepower to run in the 7s. All of that power is channeled through the SSP HP90 transmission to a QA1 carbon fiber driveshaft, a billet differential with 3.09 gears and a Per4mance Development DIRS brace and Driveshaft Shop level 5 1-piece axles.

In terms of suspension and chassis upgrades, Sipple is running the factory Bilstein dampers with a Diablo suspension controller, a full AAD Performance rear suspension package with cradle lockouts, the front and rear sway bars have been removed, lightweight TBM brakes have replaced the front Brembos, while Wilwood components are installed out back.

Finally, to make this Challenger SRT Hellcat safer for such extreme speeds, Steffco Racing and Fabrication added an 8.50 cert roll cage, Sipple installed a Gearhead Fabrications parachute mount and the factory driver’s seat has been replaced with a Kirkey race bucket with a 5-point harness and window net. The only other weight removed from the interior is the passenger seat, rear seat, seat belt assemblies and carpeting. All of the factory metal body panels are in place, with the only exterior change being the removal of the factory rear spoiler.

Jon Sipple credits his wife, Jessica Sipple, along with Ron Polidora, Rob Daughaday, Jordan Daughaday and Patrick Zabst for their help in building this Dodge Challenger SRT Hellcat to what it is today.

Best of all, Sipple believes that this SRT Hellcat will go even faster in the future.

“Future goal is to remove 245 lbs from the car to make it 4,200 with the driver and see how much deeper we can go in the 7s. On the 7-second run, we actually pulled power out of the hit so there is more in the 60 feet alone to improve on.”

We look forward to seeing Jon Sipple and his Go Mango Dodge Challenger SRT Hellcat running deeper into the 7s as he continues to stack up wins at the race track.

0 Comments