If you’ve been into Mopar® vehicles for a long time, we’re sure you’ve heard the name “Larry Shepard” and the words “Mopar” or “Direct Connection” strung together in one sentence. This Larry Shepard (not to be confused with the Larry Shepard HEMI® engine builder in Ohio) was a part of the Chrysler Race Group going back to 1967. He held the title of performance engineer until his retirement in the early 2000s. He was affectionately known as “Shep” to his co-workers and legions of diehard Mopar racers who read his tune-up tip bulletins or hung on his every word at tech seminars when he proclaimed the gospel of go-fast Mopar parts. Larry was with Mopar during the good times and bad, through corporate acquisitions and foreign owners. Larry never lost sight of what the street enthusiasts and Sportsman racers needed. He had the privilege of working under Tom Hoover, “The Godfather” of the 426 HEMI engine, and reported to the Product Planning Folks like Dick Maxwell. Throughout the decades, Larry was instrumental in creating Direct Connection and making the world, and drag strips, a better place for the diehard Mopar faithful.

At age 22, a young Larry Shepard was accepted at the Chrysler Institute of Engineering (CIE) in 1966. Here, courses were taught by Chrysler’s brightest product experts on engines, transmissions, chassis or any other driveline components. During this two-year program, Larry absorbed all the info the teachers threw at him like a sponge. Before entering the CIE program, Larry had graduated from the University of Maine with an undergraduate degree in engineering. He would earn his master’s in engineering after his time at CIE. Since Larry loved cars, he was set on working for one of the “Big Three” Detroit Automakers. “I interviewed with GM, Ford and Chrysler. GM wanted me to go to their engine assembly plant in Tonawanda, New York, but I turned it down. I wanted to design things and not just work in a plant. Ford also made me an offer, but it wasn’t to my liking, so then I heard back from Chrysler and the offer they presented to me was similar to that of Ford, but a bit better, and I could see they were supporting their muscle car owners with a performance parts program,” said Larry.

By 1967, Larry had received his master’s degree in engineering and was quickly put to work in Chrysler’s Transmission Lab in Highland Park, Michigan. “I wanted to get into Chrysler’s Race Group but first I had to do my regular assignment. By 1968, I amassed enough seniority and was accepted into the race group. My first project was on the Super Stock HEMI Barracuda and HEMI Darts. My ‘office’, if you will, was a table and chair at the infamous Woodward Garage,” smiled Larry. “The building was an old dealership that Hoover and some of the Ramchargers team members used during the early 1960s. It was a great location, off the beaten path, and away from the prying eyes of the corporate execs. Dan Mancini was the manager of the Woodward Garage and we got along great,” noted Larry. “We had a handful of mechanics and fabricators that worked on both drag cars and NASCAR vehicles. We were finalizing the 1968 Super Stock HEMI A-Body ‘Engineering Mule’ car and took it out for additional testing,” recalled Larry.

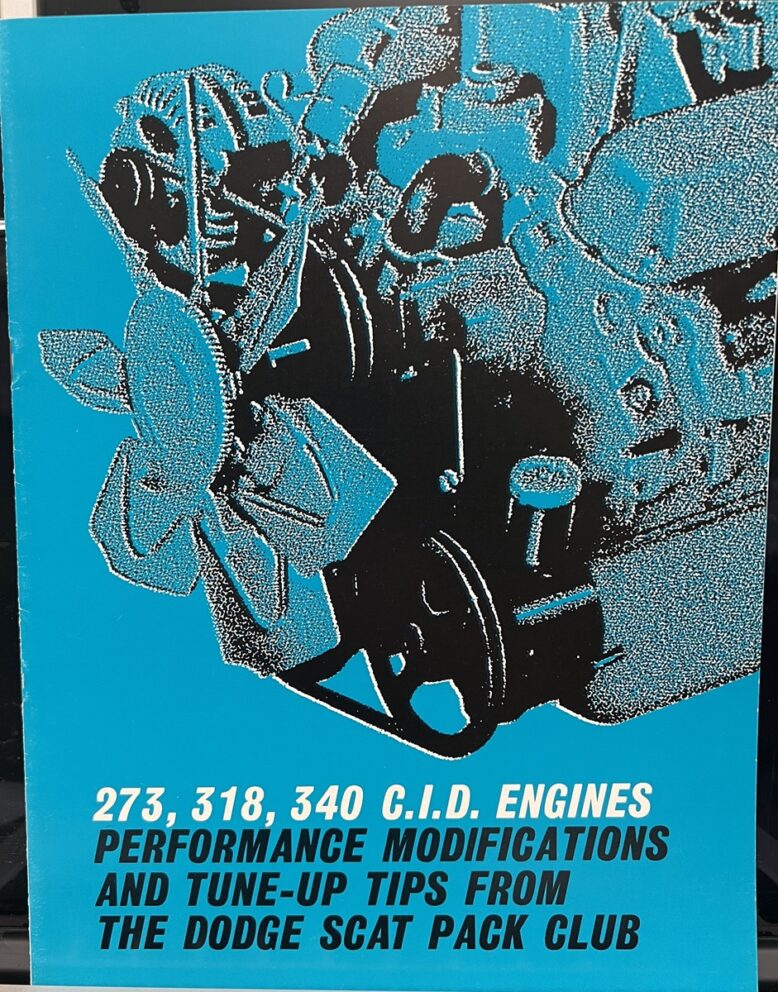

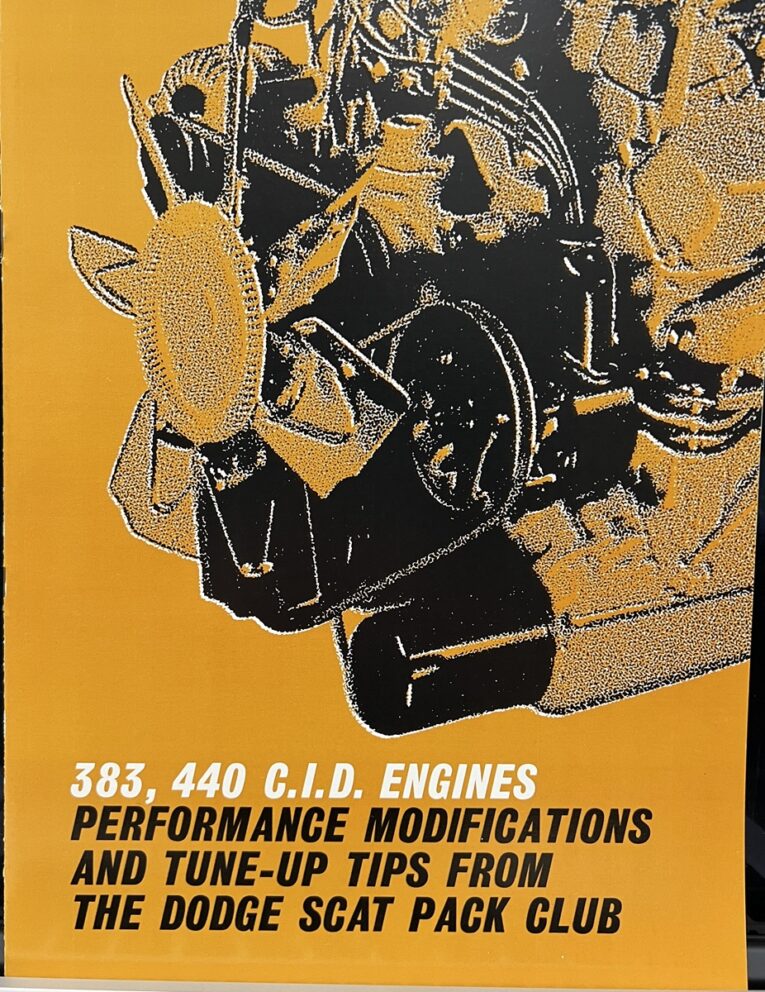

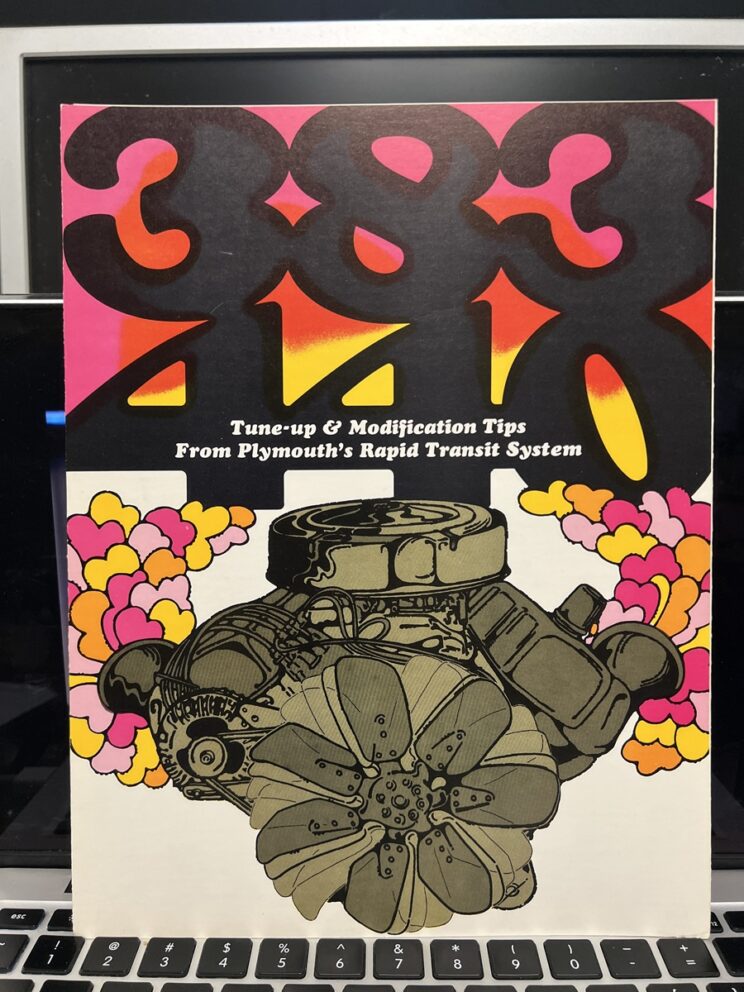

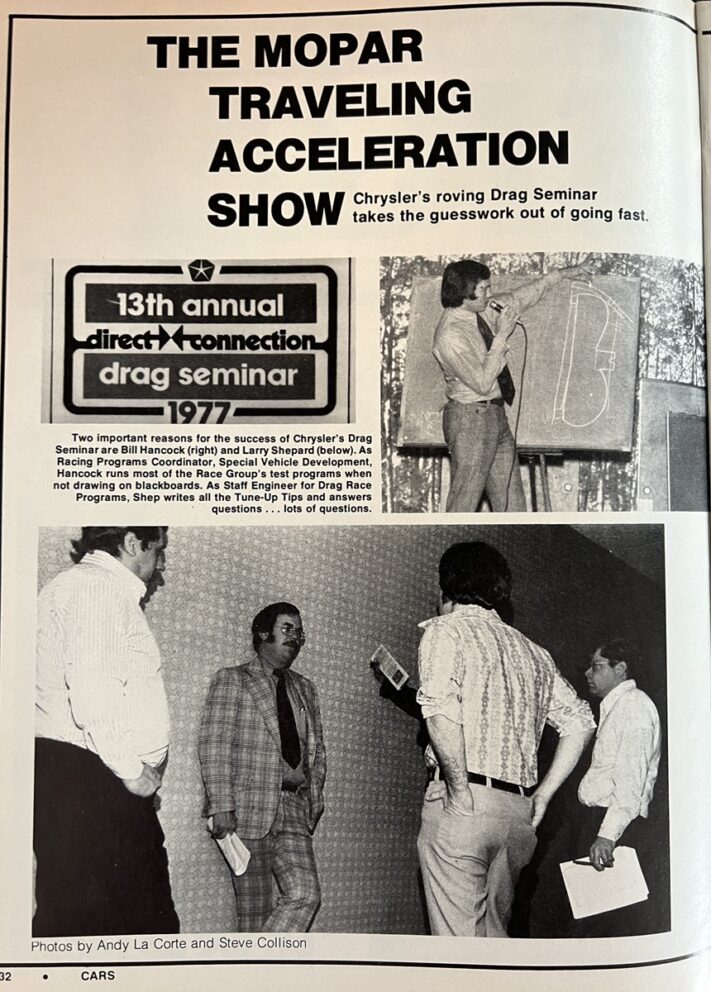

After working on racing suspension systems, by February of 1970, Larry moved over to another role within the Chrysler Race Group, and it made sense. Since Chrysler was at the forefront of the muscle car movement during the 1960s and early 1970s, they were also winning the battle in Super Stock and Pro Stock at NHRA and AHRA drag strips across the country. Because of his background, Larry was also tasked with writing the early “Tune-Up Tips” booklets that both Dodge and Plymouth offered through their Scat Pack and Rapid Transit System muscle car marketing programs. “We saw the need to tie in what Chrysler was doing on their early ventures into offering performance parts and felt that offering tech tips to owners would create more demand for performance. Also, the aftermarket gravitated towards the Chevy and Ford racers and Chryslers were left out in the cold. From what we learned racing in Super Stock and eventually Pro Stock, that could be applied to bracket racers and even the guys on the street,” noted Larry.

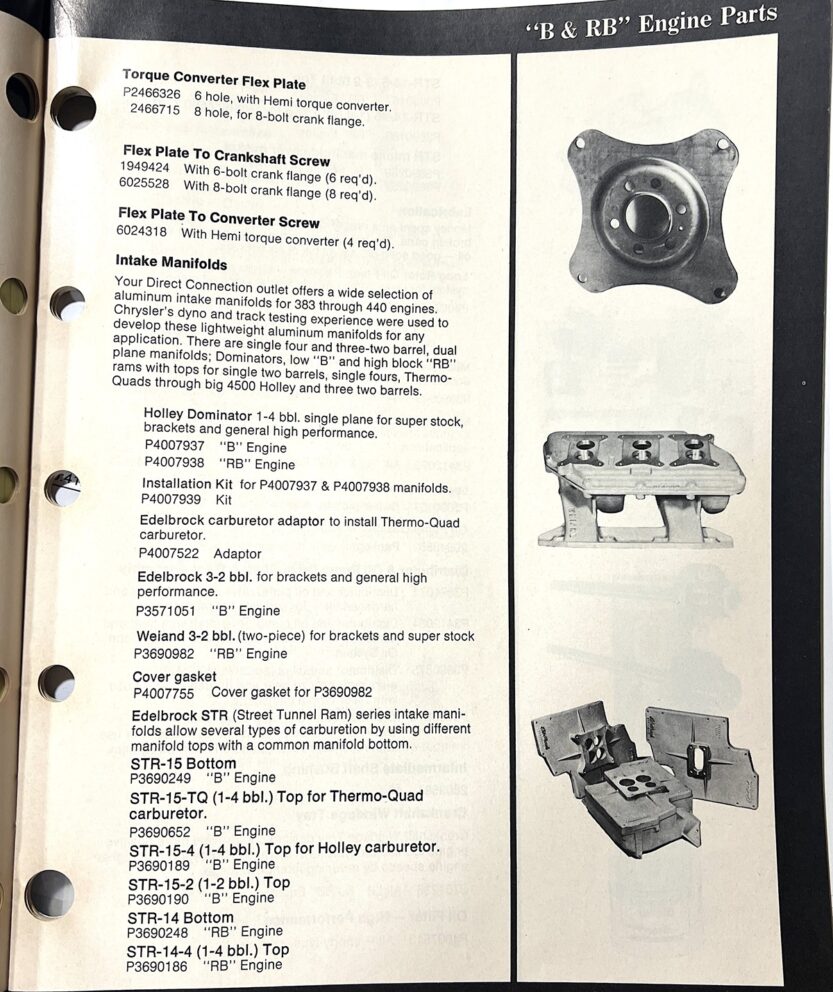

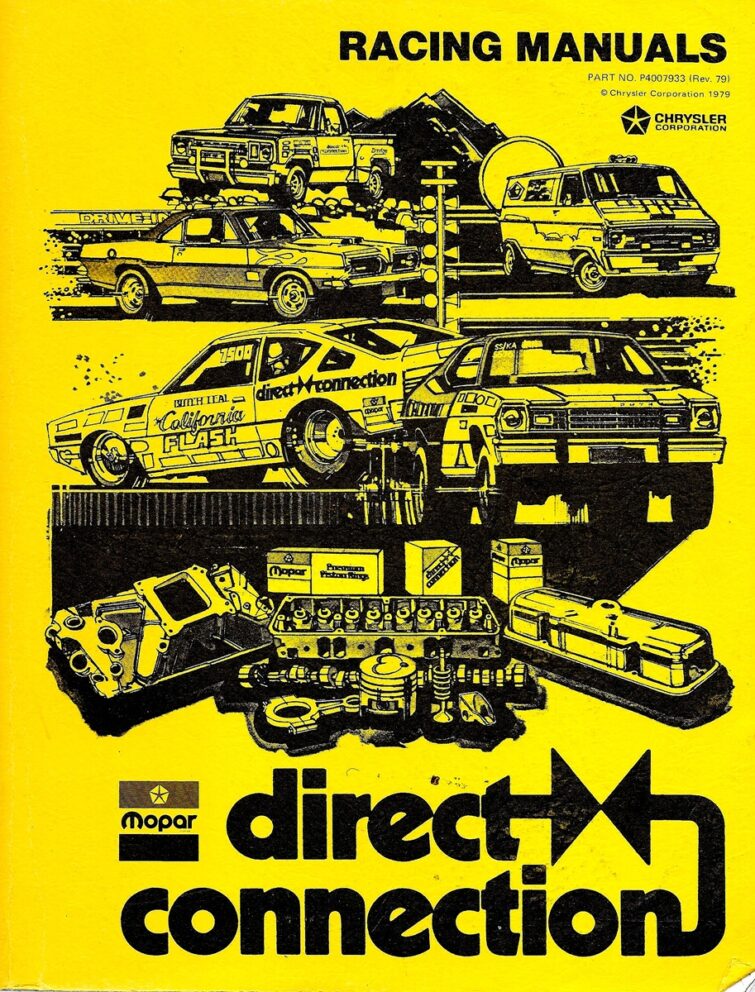

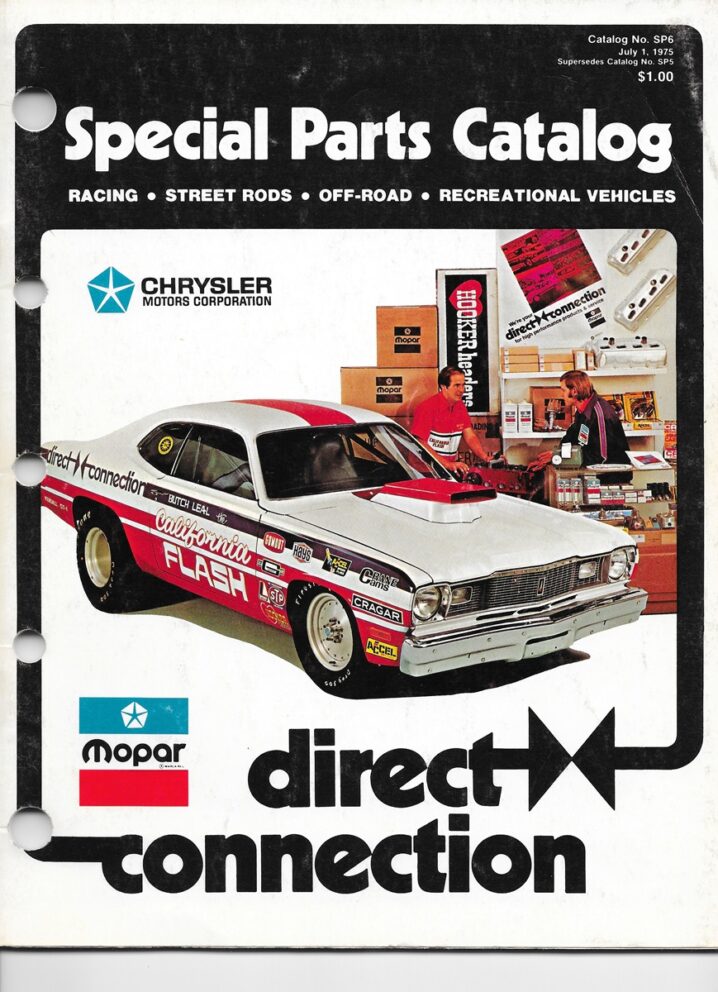

Larry also designed and developed additional products to support Mopar racers and that also was a priority for him. It was Larry’s mission to provide Mopar drag racers every advantage over their competition. “I was tasked with designing big block intake manifolds. One that stands out is the 440 Six Pack/Six Barrel piece that was used for Super Stock. It was a two-piece design with improved runner flow and volume, and we had Weiand manufacture this piece. We tested it along with many other parts at Milan Dragway. Mopar sold the manifold through our performance parts programs that would become Direct Connection in 1974,” recollected Larry. The intake manifold was just one of many products Larry introduced during the dawn of Direct Connection. “We looked at Direct Connection as a function of the company (Chrysler) at the time, our race group was great as it ever was, but the budget cutbacks of the early 1970s did hurt. The racers didn’t go anywhere, so we needed a way to support them. The Direct Connection parts program was a way to do that.”

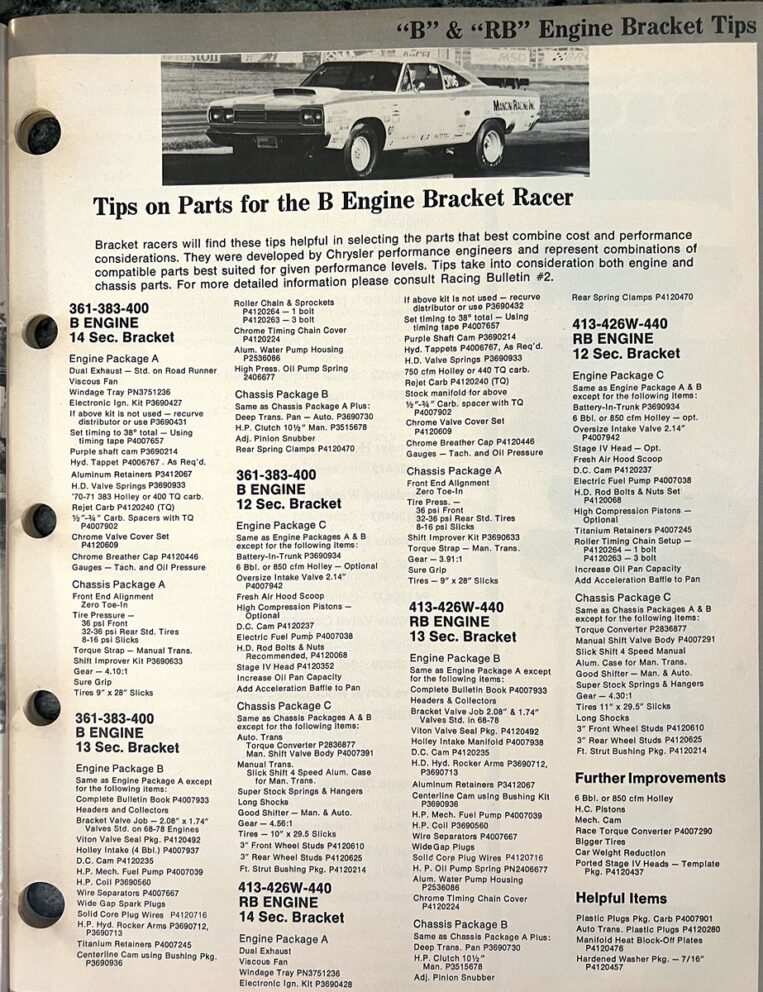

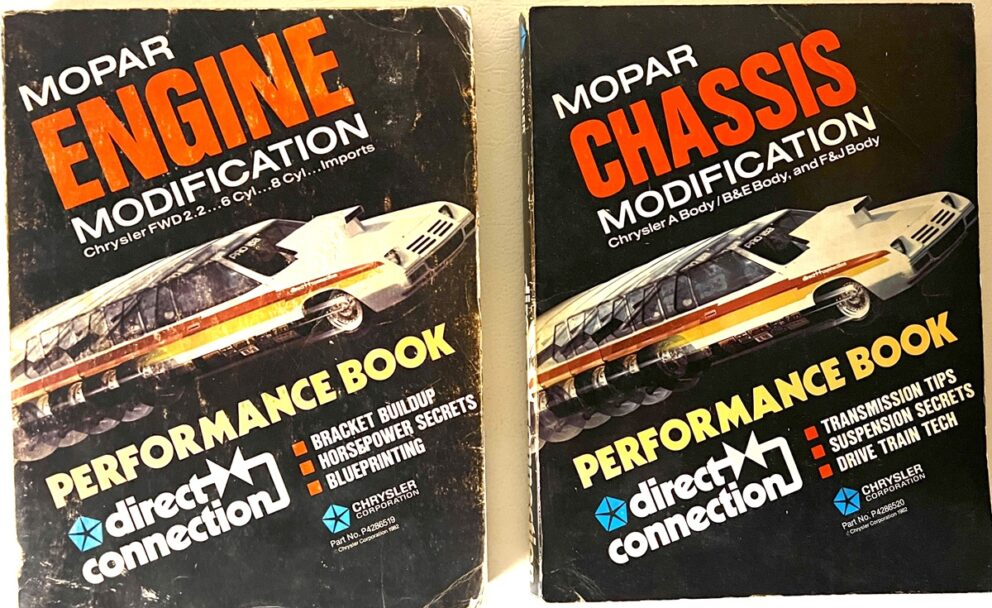

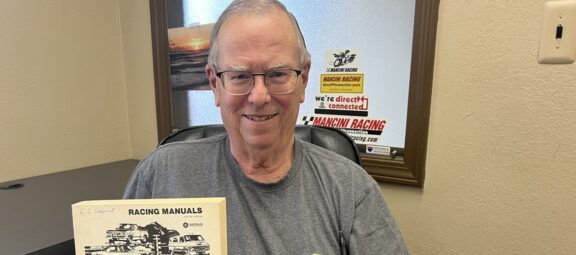

Other notables were “Purpleshaft” camshafts designed and developed specifically for Mopar engines. These were an instant hit with folks running 340, 383, 440 and Street HEMI powerplants. Larry leveraged the engineering knowledge base from the dyno cells of Chrysler’s HQ in Highland Park, Michigan. This also produced a winning formula that led to Larry creating “Engine Receipts” with specific ET goals. “We went further than what GM and Ford did. Direct Connection outlined what customers would need and provided the recommended parts list to achieve their goals. It was straight from the factory, tested, proven and worked. We offered factory-engineered intake manifolds, cylinder heads, camshafts, oiling systems, fuel systems, rear gear ratios, leaf springs and much more. These were the same questions I’d answer from customers sending in letters or calling me back in the early 1970s, so I got the idea to publish the answers in our performance catalogs and manuals,” said Larry.

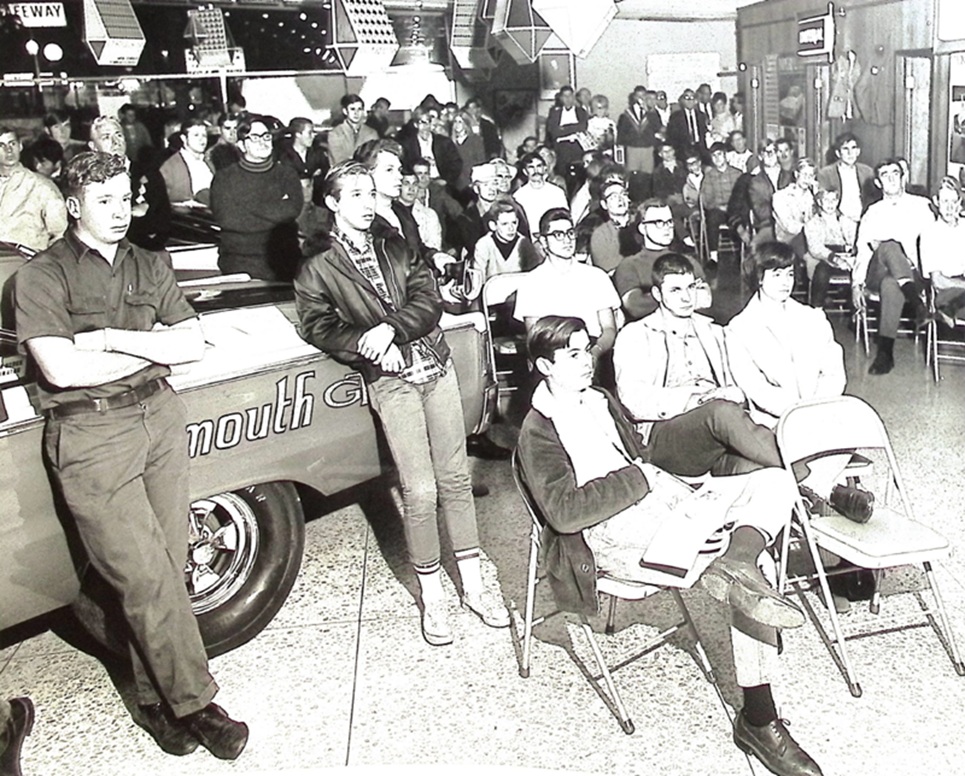

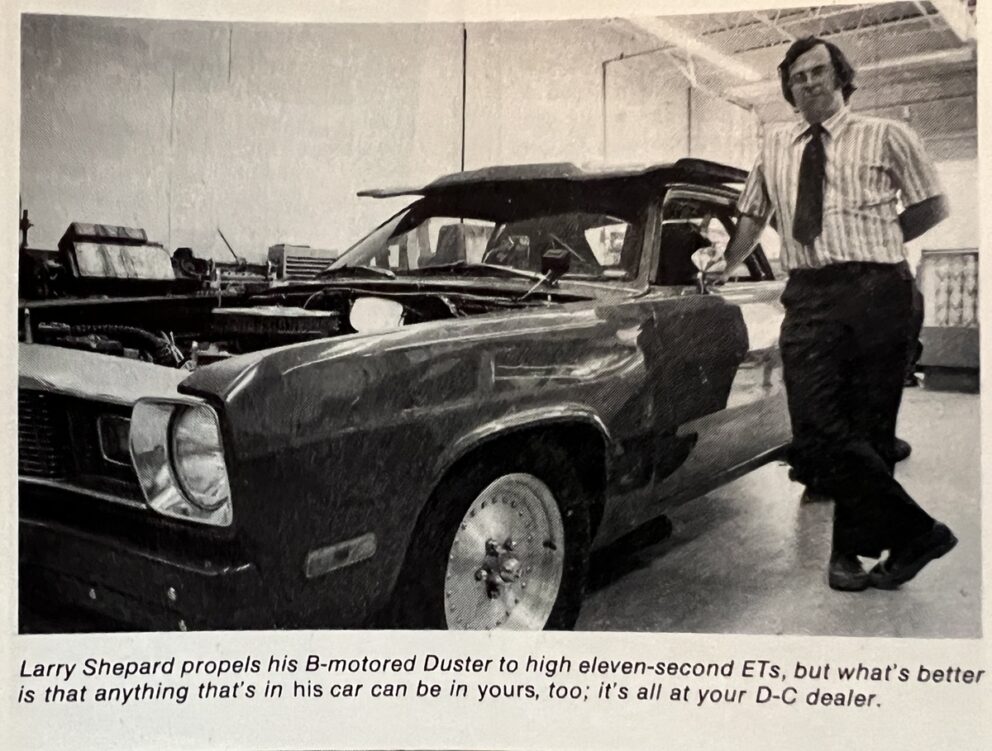

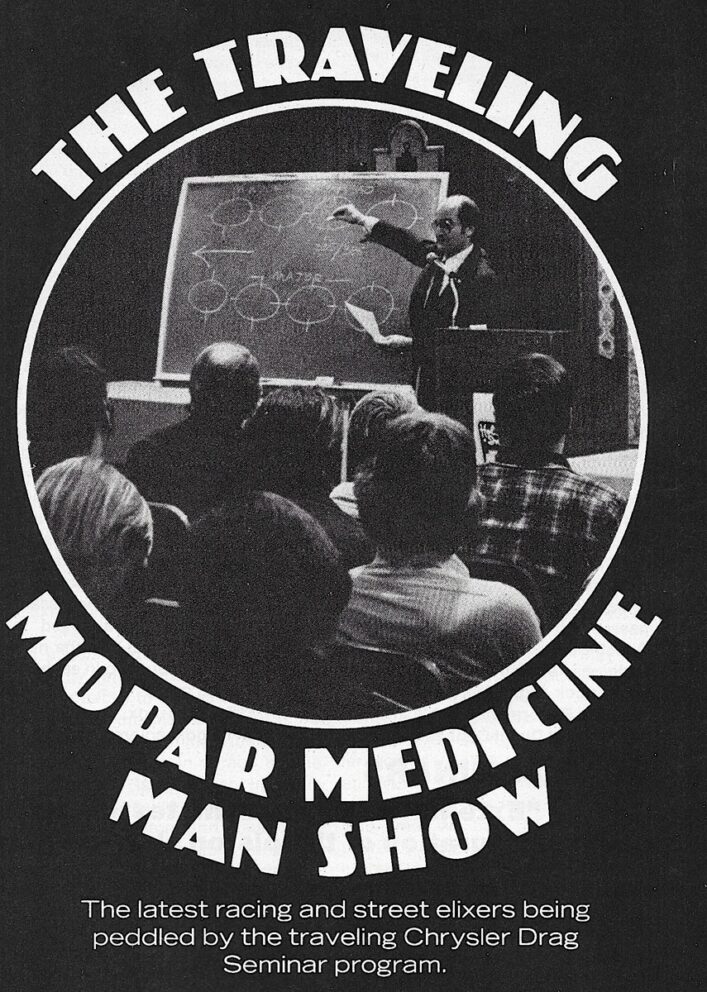

The Muscle Car movement may have vapor locked by the 1970s, but Larry Shepard and his Direct Connection colleagues were undaunted. Taking a note from the Sox & Martin Plymouth and Dick Landy Dodge Supercar Clinic dealer programs that crisscrossed the country from 1967 to around 1971, Larry suggested holding Direct Connection Tech Seminars on the road to reach more enthusiasts and these were very successful. Direct Connection also had a few test cars and Larry helped build and race a unique Duster that was powered by a Big Block chock full of Direct Connection parts and raced at Milan Dragway. Larry used the Duster to create packages for bracket racers and enthusiasts.

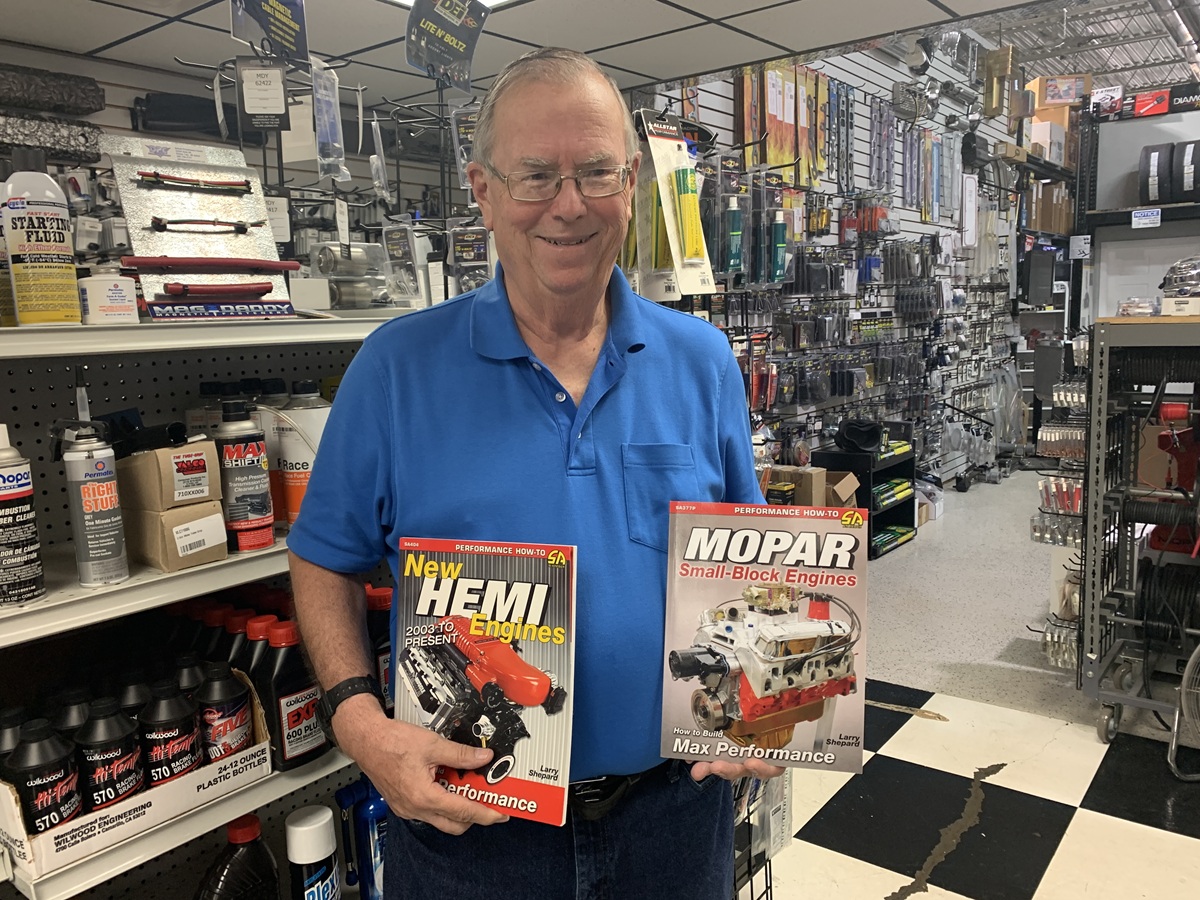

As the 1970s faded into the 1980s and soon the 1990s, Direct Connection would become Mopar Performance Parts, but Larry never lost focus on the mission. His depth of knowledge and commitment never waned. Even in retirement, Larry can’t stay still and continues to use his knowledge today to help Mopar racers by publishing many books for the Small Block Mopar and the modern GEN III HEMI engines.

So thank you, Larry “Shep” Shepard, for keeping the Mopar herd from going astray!

0 Comments