Pre-Run Checklist

FLUID LEVELS

ENGINE

The Drag Pak's 354-cubic-inch supercharged HEMI® V8 engine is delivered with (7) quarts of Shell 5W-40 Rotella T6 oil (Mopar part number 68001332PA = (1) quart). The engine does not come with a dipstick, but there are provisions to install one. It's recommended that the oil and filter be changed every 20 runs or less.

TRANSMISSION

Check the fluid level in the Drag Pak’s transmission with its locking dipstick, while on level ground. Follow these steps to ensure an accurate fluid reading on the dipstick:

- With a crew person sitting in the vehicle with their foot on the brake, the engine needs to be idling with the transmission in 3rd gear.

- The transmission fluid level should measure at the “full” line on the dipstick.

- Do not race the car if the trans fluid level is not at the full mark on the dipstick, or transmission damage might occur and performance will be hampered.

- Start the car and run it for at least one minute to build heat in the trans fluid.

- Shut the car off and drain the fluid from the trans pan. The Drag Pak's transmission pan holds approximately (6) quarts.

- During refilling, first add (5.5) quarts of transmission fluid and take a reading on the dipstick — see procedures above. Add additional transmission fluid until the level is at the "full" line.

- We recommend using Redline D6 Transmission Fluid. Don’t mix different transmission fluids or damage may occur.

- The transmission has a heavy-duty metal screen transmission oil filter. Under normal race conditions, the transmission oil filter only needs to be changed at least once every season.

RADIATOR

The Drag Pak is delivered with a 50/50 mix of coolant and water. It's recommended that the cooling system be drained and the 50/50 mix be replaced with distilled water prior to the vehicle making a run down the drag strip. Make sure to purge the cooling system of any air trapped in the system. Refer to the Competition Setup section for detailed instructions.

INTERCOOLER

It's important to fill the intercooler tank with a mix of water and ice prior to the run. The recommended mixture is 1/3 water and 2/3 ice. Top off the intercooler tank and prime the intercooler pump prior to leaving the pits and heading to the staging lanes.

BREAK-IN & SETTINGS

ENGINE BREAK-IN

The Drag Pak's 354-cubic-inch supercharged HEMI V8 engine is run on a dyno prior to installation. No break-in procedures are required prior to competition.

TRANSMISSION BREAK-IN

The three-speed automatic racing transmission is run on a trans dyno. No additional break-in procedures are needed prior to competition.

FUEL PRESSURE SETTINGS

Without the engine running, the fuel pressure is pre-set and should have a static reading of 70 psi. Refer to the Holley Digital Dash if any adjustments are needed.

LUG NUT TORQUE SETTINGS

Check lug nut torque on all four wheels prior to every run. Rear wheels need to be torqued to 130 ft.-lbs. and fronts should be 95 ft.-lbs. This setting is the same for both the BOGART and WELD wheel options.

FRONT AND REAR TIRE PRESSURE

Tire pressure is crucial to ensure maximum traction and proper handling on the vehicle. The rear slicks are pre-set to 20 psi and the fronts are at 40 psi. No pressure adjustments might be needed based on track and weather conditions. The tire manufacturer recommends a pressure range of 38-40 psi in the front, and 18-28 in the rear.

RIDE HEIGHT

The ride height measurements need to be taken in the middle of the front and rear wheel arches on a level surface. The recommended measurements are 27-¾ inches front and 28 inches rear. Refer to the Competition Setup section for more details.

BREAK-IN & SETTINGS

ENGINE BREAK-IN

The Drag Pak's 354-cubic-inch supercharged HEMI V8 engine is run on a dyno prior to installation. No break-in procedures are required prior to competition.

TRANSMISSION BREAK-IN

The three-speed automatic racing transmission is run on a trans dyno. No additional break-in procedures are needed prior to competition.

FUEL PRESSURE SETTINGS

Without the engine running, the fuel pressure is pre-set and should have a static reading of 70 psi. Refer to the Holley Digital Dash if any adjustments are needed.

LUG NUT TORQUE SETTINGS

Check lug nut torque on all four wheels prior to every run. Rear wheels need to be torqued to 130 ft.-lbs. and fronts should be 95 ft.-lbs. This setting is the same for both the BOGART and WELD wheel options.

FRONT AND REAR TIRE PRESSURE

Tire pressure is crucial to ensure maximum traction and proper handling on the vehicle. The rear slicks are pre-set to 20 psi and the fronts are at 40 psi. No pressure adjustments might be needed based on track and weather conditions. The tire manufacturer recommends a pressure range of 38-40 psi in the front, and 18-28 in the rear.

RIDE HEIGHT

The ride height measurements need to be taken in the middle of the front and rear wheel arches on a level surface. The recommended measurements are 27-¾ inches front and 28 inches rear. Refer to the Competition Setup section for more details.

If you need to change the Drag Pak’s ride height, you can do this by adjusting the shocks and/or springs. When adjusting the shocks, it’s recommended that you raise the vehicle and let the suspension relax before changing ride height. Gloves are recommended when using the proper Bilstein spanner wrench (part number B4-XS1-Z001A00) to avoid injuring your knuckles.

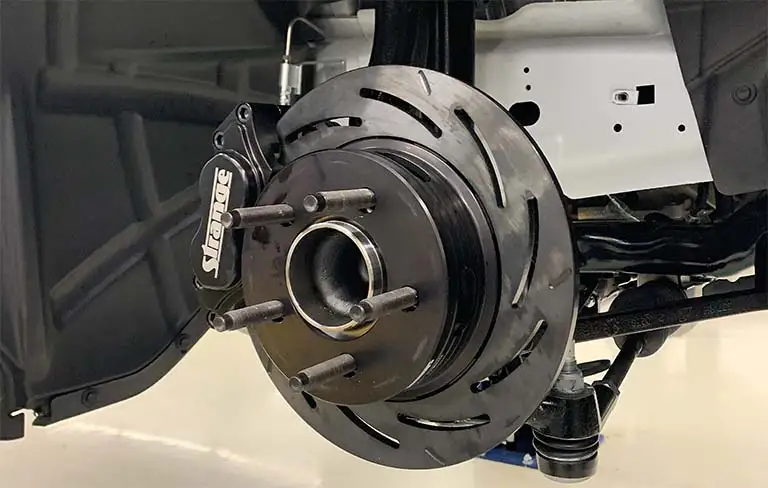

BRAKES

Before the Drag Pak is raced, it's imperative that the front and rear brake pads get seated properly to the rotors. This process, known as 'bedding', is when brake pad material is transferred to the rotor surface. The heat generated will finish the curing process of the brake pad. Click here for the recommended brake bedding procedures.

WARNING: Failure to properly bed-in the brakes may result in loss of brake performance.