– Ultra rare HEMI® ragtop that has survived the years

– Unusual options: Power windows, clock, but a “no radio” car!

– A sleeper for sure, save for two small “426 HEMI” fender emblems

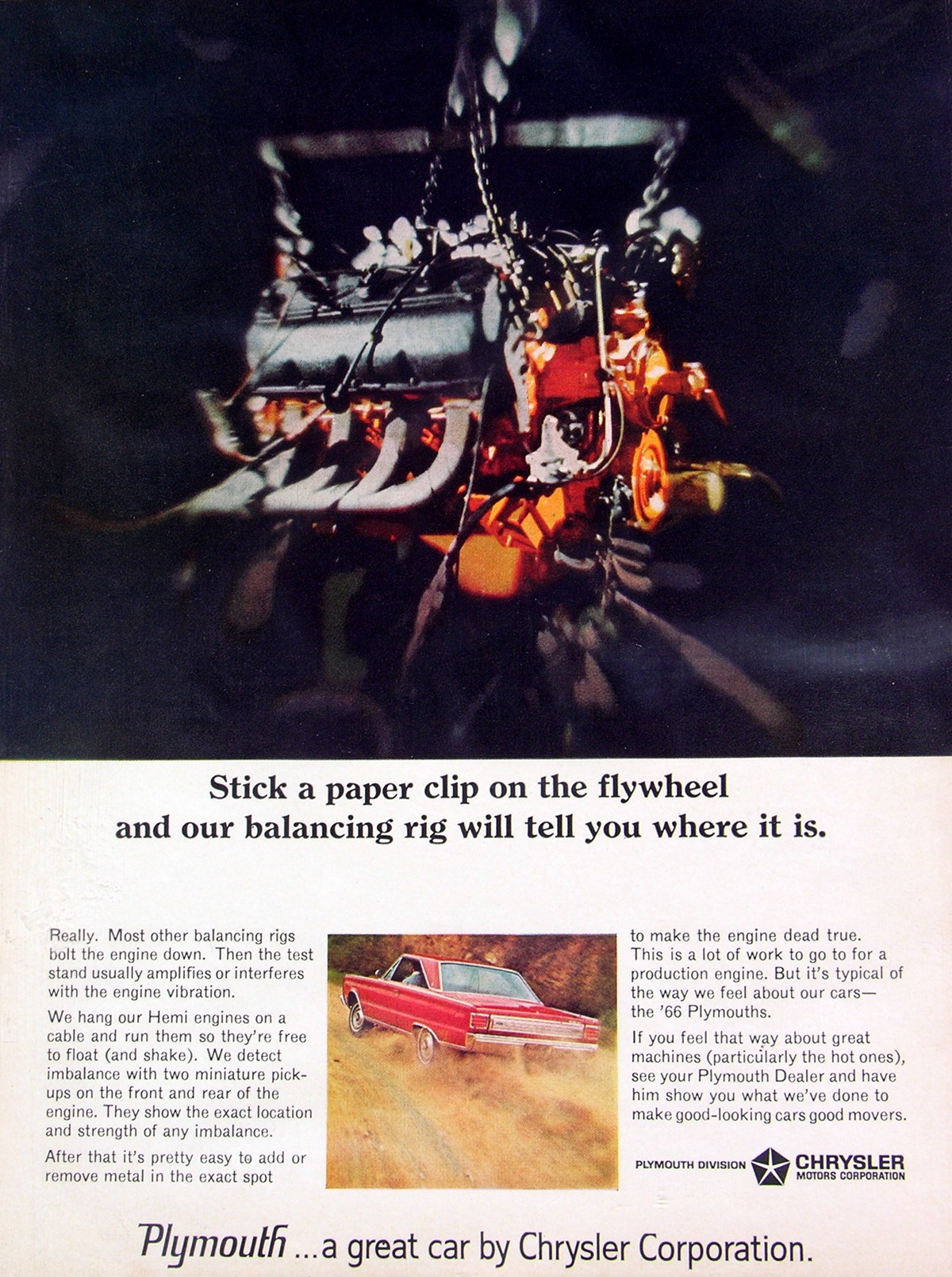

NEW HEMI ENGINE FOR CONSUMER STREET MARKET

When the mighty 426 HEMI engine came out in February 1964, it was an all-out racing engine built for NASCAR (National Association for Stock Car Auto Racing) competition, as well as for drag racing applications. This was a radical powerplant – too wild for street use. Fitted with 12.5:1 c/r (compression ratio) pistons and a racing camshaft with 312 degrees of duration, the 1964 and 1965 Race HEMI engines were exotic race-bred pieces built for pure speed!

Race HEMI engines featured aluminum heads, aluminum intake manifolds (2×4 cross-rams on drag applications, magnesium material in ’65, and single 4-bbl units for stock car racing use) and fabricated tubular exhausts. Holley race carburetors without choke provisions were used and it’s easy to see that these were not “run to the grocery store” engines by any stretch of the imagination.

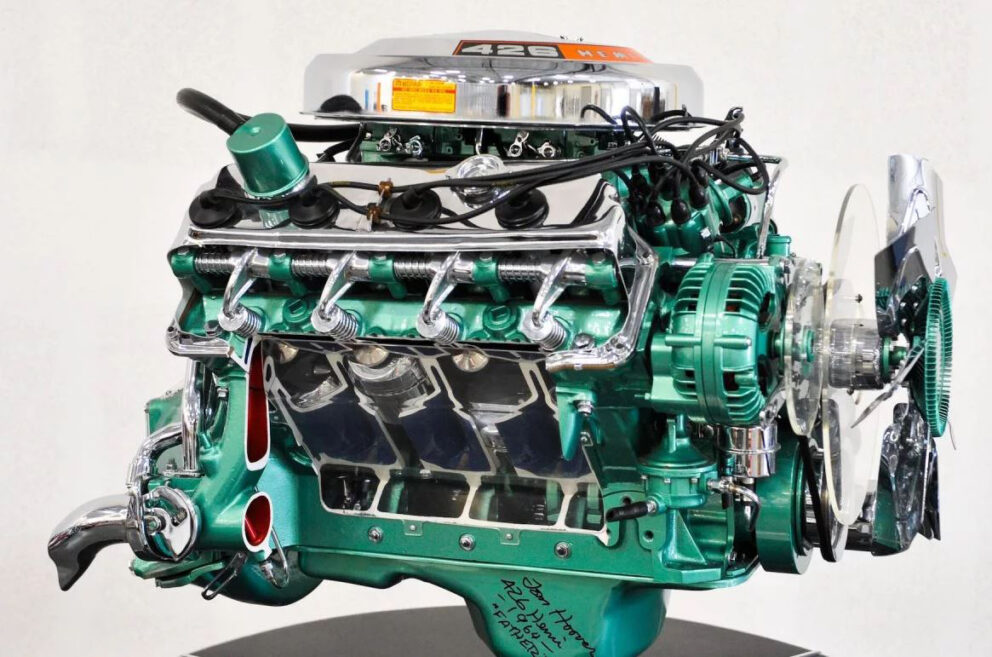

Chrysler decided to offer a “street” version (pictured) of the 426 HEMI engine for the 1966 model year. The race version clearly had proven itself on the NASCAR tracks, as well as the nation’s drag strips, so for ’66 it was time to offer the 426 hemispherical combustion chamber-headed mill to the public. An “A102” program (internal factory paperwork) was put into place in early 1965 at Chrysler to authorized appropriate design and drafting work to begin. Soon these streetable engines were factory fitted in B-body Dodge (Coronet, Charger) and Plymouth (Belvedere, Satellite) models.

Both the Dodge and Plymouth divisions offered the newly designed “Street” 426-cid HEMI engine in their B-body cars for the 1966 model year, and this article, along with feature car, focuses on the Plymouth versions.

These Street HEMI engines were produced at Chrysler’s Marine/Industrial Division in Marysville, Michigan, and the engineers came up with a rather unusual manner to balance them. Rather than the normal procedure of bolting the engine to a stationary stand and running it to check for balancing, the Street HEMI engines were suspended in mid-air (hung from cable on their special HEMI balancing rig) and exhaust was hooked-up to flexible tubing, as were fuel/oil lines, and then the unit was fired up right then and there to test for engine balance.

Two small electronic pickups are mounted to the front/rear of the engine (vibration damper up front, flywheel or torque converter on HEMI engines destined for automatics) and then balance imperfections were detected and solved while the engine ran unattached to a fixture. The idea here was for any vibrations to be clearly visible and the engine balanced until it ran smooth, and floated shake-free.

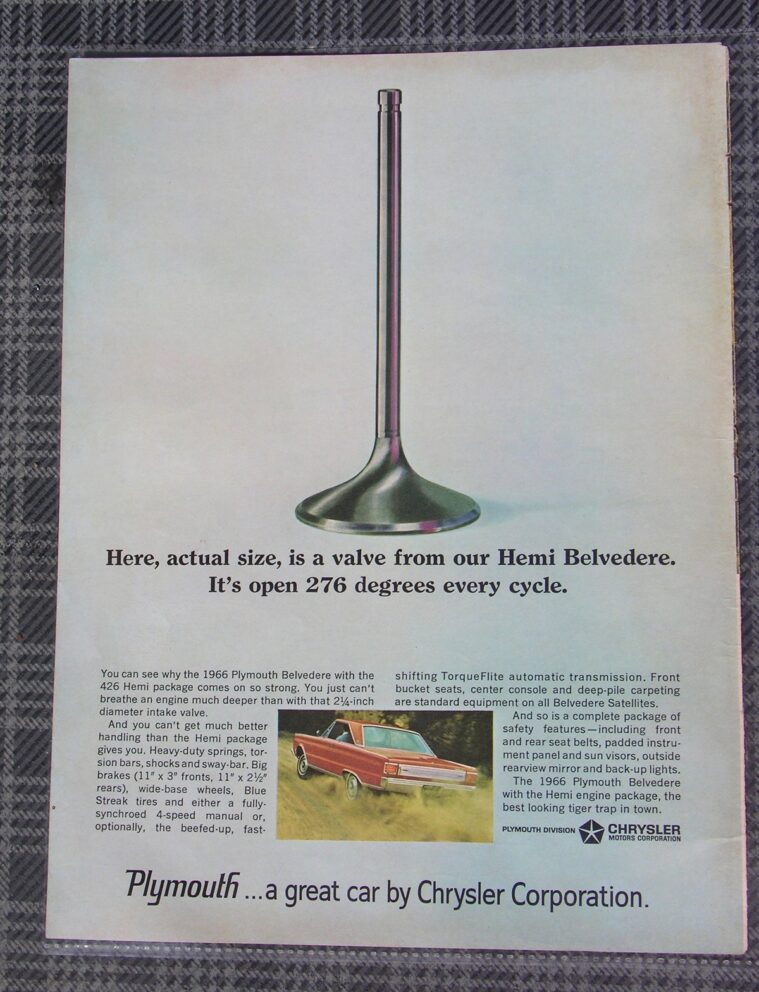

Well, it did take an extra $907.60 in 1966 to have the honor of telling your neighbor, “Yeah, it’s got a HEMI in it.” The engine was fitted with domed, forged pistons (10.25:1 c/r, extruded aluminum alloy, tin-coated) and this lower ratio allowed it to run on the then-available premium pump gas. Other revisions included a slightly tamer camshaft, with a new profile (changing valve duration from 312 to 276 degrees of duration) that provided smoother low-speed operation while still allowing ultra-efficient high-RPM breathing and overall power. Mechanical lifters were still retained.

Cylinder heads were cast iron and were fitted with tulip-shaped valve heads (2.25-inch intake, silicon-chrome XB material, 1.94-inch exhaust, 21-4N chrome-manganese material w/welded satellite face) and forged steel rocker arms were used like on the race version, as well as lightweight pushrods to reduce valve train inertia.

Street HEMI ignition (double-breaker) now featured a vacuum advance mechanism in the centrifugal design (where the race version was strictly a centrifugal unit) and special “cold” spark plugs were fitted – Champion N-9Y as compared to former N60Y racing plugs.

Atop the new Street HEMI engine sat a new sand-cast aluminum intake manifold of semi-high-rise configuration – designed for tandem-mounted twin Carter AFB 4-barrel carburetors (4139S and 4140S), connected to one another via a staged throttle linkage arrangement. A 3/8-inch fuel line and high-capacity fuel pump was part of the package. The inline 2×4 system used a single, over-sized, unsilenced air cleaner of low-restrictive design.

Exhaust manifolds on this streetable HEMI engine were made in cast-iron material and the 4-into-1 units were flowed into a pair of large mufflers via a 2 ½ dual exhaust system with cross-over. The passenger’s side manifold had a built-in heat control valve to operate the choke on the rear carburetor, as the front carb had no choke.

Bore finish specified was slightly smoother (to help control oil consumption) and like the Race HEMI engine, a double roller timing set was retained. In fact, other than the lower c/r pistons, the internals were identical to the competition engine (heavily webbed cylinder block, shot-peened and chemically treated forged crankshaft, dropforged I-bean connecting rods, Tri-Metal MS-2355 bearings, and number 2, 3 and 4 main bearing caps have reinforcement via extra bolts to anchor the crankshaft). This Street HEMI engine was a stout unit just like the prior race-only version…

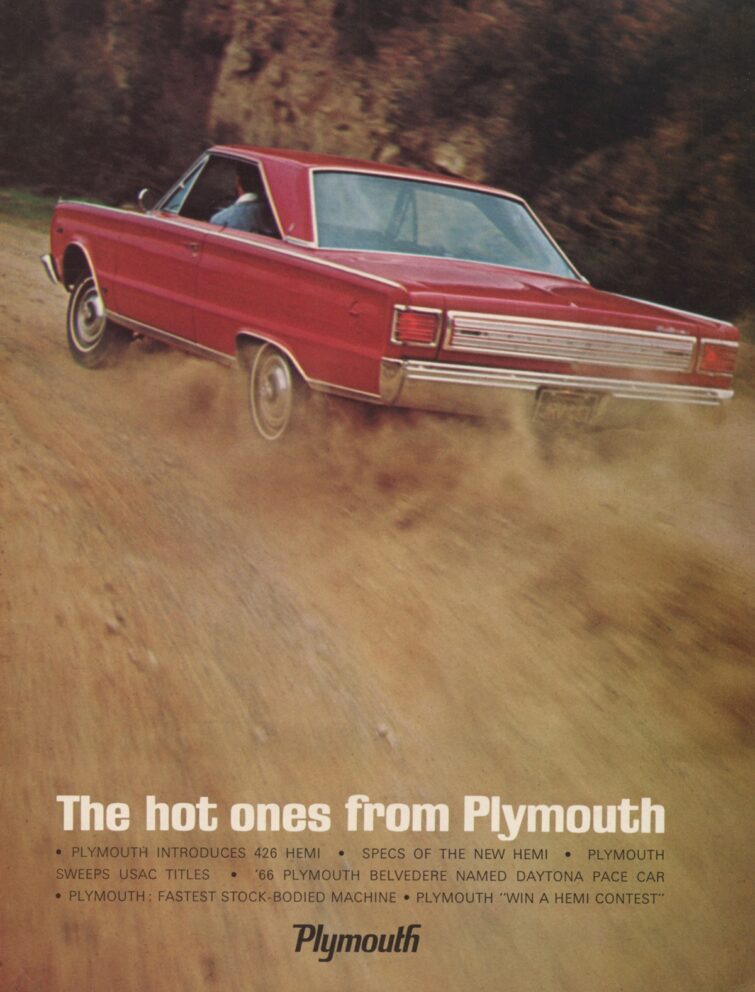

Docile-appearing Plymouth Belvedere II looks like a regular unassuming vehicle … until the 426 HEMI powerplant under the hood is discovered!

BIG HEMI ENGINE

Here’s how the Plymouth Advertising Dept. described it: “And then there’s the HEMI engine itself. Aside from some changes to make it operate satisfactorily on the street (like 10.25:1 compression ratio so you can use pump gas instead of carrying Av-gas with you, and a choke on the rear primaries so you can start it outdoors in winter), the Belvedere HEMI is very similar to the HEMI set-up of the specially prepared Daytona stockers and the drag strip top eliminators.”

HOOD ORNAMENT TELLS ALL

Unique Red color hood marker states “426” and that for 1966 only meant one thing – HEMI POWER! During the 1965 model year, there was a “426” engine available on production cars; however, it was the wedge-head version, not the HEMI.

RARE: NO RADIO CONVERTIBLE

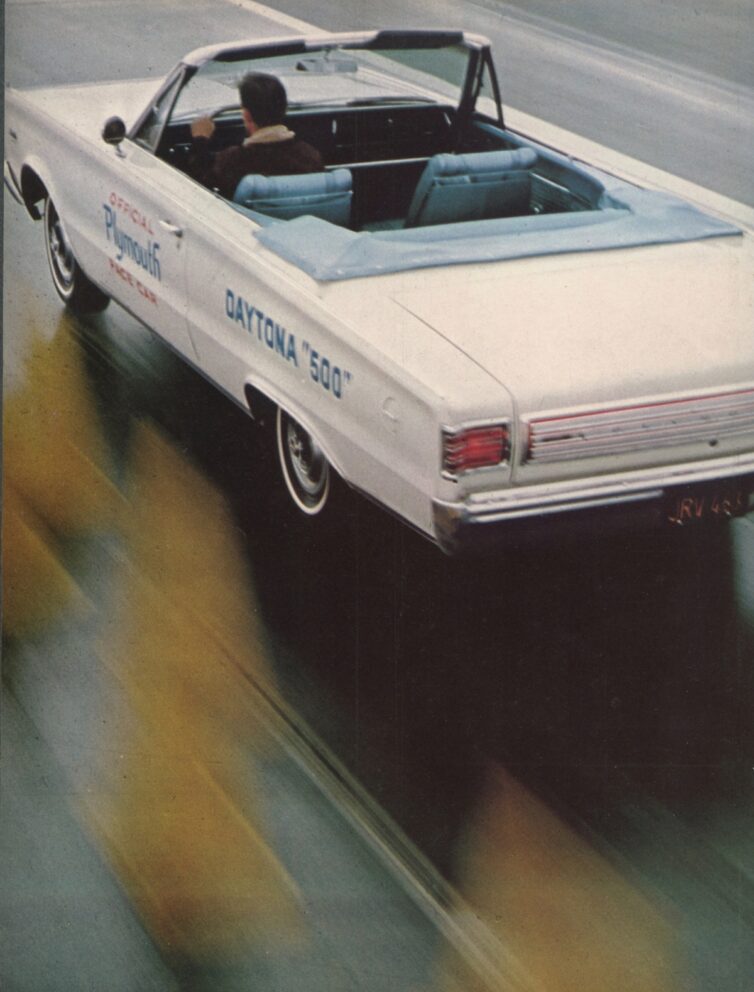

With a vehicle curb weight upwards of 4,000 pounds, the feature car, a HEMI engine-powered 1966 Plymouth Belvedere II convertible, is in pristine condition! Looking closely, there’s no radio antenna, this car was not equipped with a radio from the factory, for unknown reasons. From the rear there’s no clue that the HEMI engine lurks under the hood, just dual exhausts which were available with lesser powerplants.

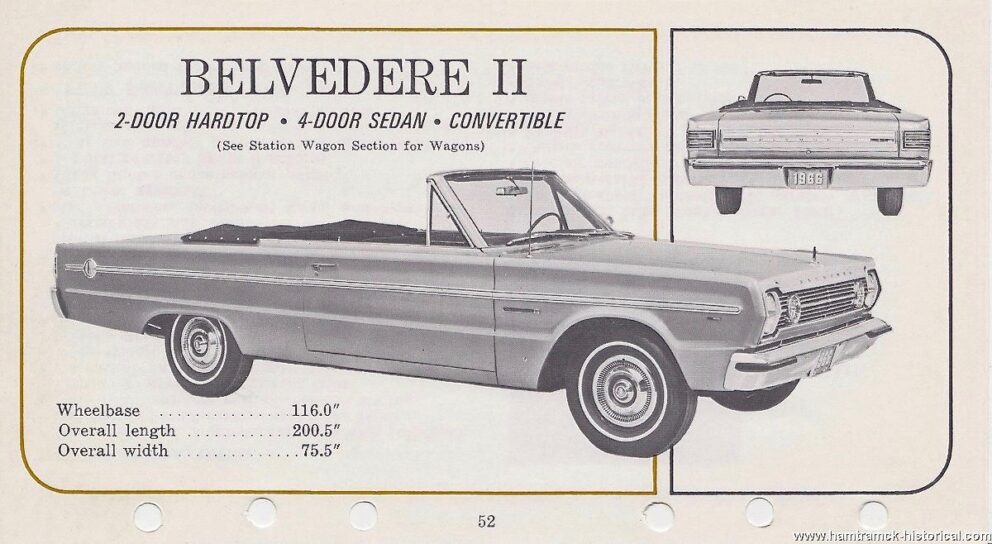

The new-for-1966 Belvedere (aka “B-body”) was some three inches shorter than the version it replaced but still rode on the 116-inch wheelbase. The new style was sleek and the look was fresh. The revamped car was introduced September 29, 1965, marketed as an “intermediate-sized” entry and featured square bodylines that were beautifully created by Elwood Engel, Chrysler’s Design Chief. He used knife-edge lines on top of the fenders, doors and quarter-panels, with slab siding but featuring a gentle contour that ran the length of the body. This was a refreshing shell on the original chassis that Virgil Exner debuted for 1962. A major improvement!

To demonstrate that the new Street HEMI engine was a true road-worthy machine, the factory provided Motor Trend Magazine (for their April 1966 issue) a car to test over a 4,000-mile cross-country trip. Plymouth’s VP Robert Anderson handed over the keys to MT editor Donald MacDonald in Detroit and soon the potent Plymouth (a HEMI engine-powered Satellite hardtop) was on a trek that zigzagged through long stretches of road in Kentucky, Mississippi and Texas, aimed toward California via New Orleans.

Fuel consumption was an issue and the text of the article questions the size of the fuel tank chosen: “When you’re driving this job on a credit card, however ubiquitous the brand, or late at night, your thoughts tend to dwell on the guy in engineering who decided that a 16-gallon re-fill was big enough for any Belvedere, six or HEMI,” MacDonald wrote. And he went on to add: “While cruising, we never did engage the front 4-barrel carburetor, which comes in at 40% of throttle movement. We inadvertently did, however, several times while accelerating. There is noticeable throttle resistance at the point of engagement, and when it cuts in, you feel like you’re riding shotgun on a rocket. It is sort of an all-or-nothing affair guaranteed to scatter rubber smoke, and sometimes traffic, in all directions.”

The actual fuel mileage was never reported in the article; however, it sure appeared that the test drive was a fun and enjoyable assignment. “In some states we passed through, the law says to stop at all rail crossings. We suspect the reason is not so much that a train might be coming through, but to protect you from becoming airborne.”

Hitting the gas stations on the way, the test car got lots of “oohs and aahs” from the service station attendees. (Remember this was back in the day when they used to actually pump your gas and check the oil if requested.) The article continued:

“It was pretty difficult to get any of the people in the 20-odd gas stations where we stopped en route to go about their business with dispatch. Once the hood was opened—and believe us, it was opened as soon as the signs on the fender were spotted—it was all talk and no action. The engine is, we admit, an impressive package, and one whose name is amazingly well known in the hinterlands. The mechanical inspection inevitably led to a cockpit check, and if one attendant mentioned it, 20 did: What’s that 6 grand tach doing there? It ought to go to at least 8500.’ We agree, and also think that the speedometer should go higher than 120. It’s too easy to kink the needle.”

INTERIOR

Three observations of the interior: radio block-off plate, dash-mounted clock, power windows. The bench seats were the “H4B” vinyl trim upgrades, an optional item.

UNDERHOOD DETAILS

A pair of Carter AFB (Aluminum Four Barrels) sat on top of these 1966 engines, one punch of the throttle provided 8 barrels of forced air-fuel mixture and some instant tire smoke! Progressive linkage was used, and the rear carb (primary use) featured a choke for aid in cold starting. A dual-plane manifold was used, cast in aluminum.

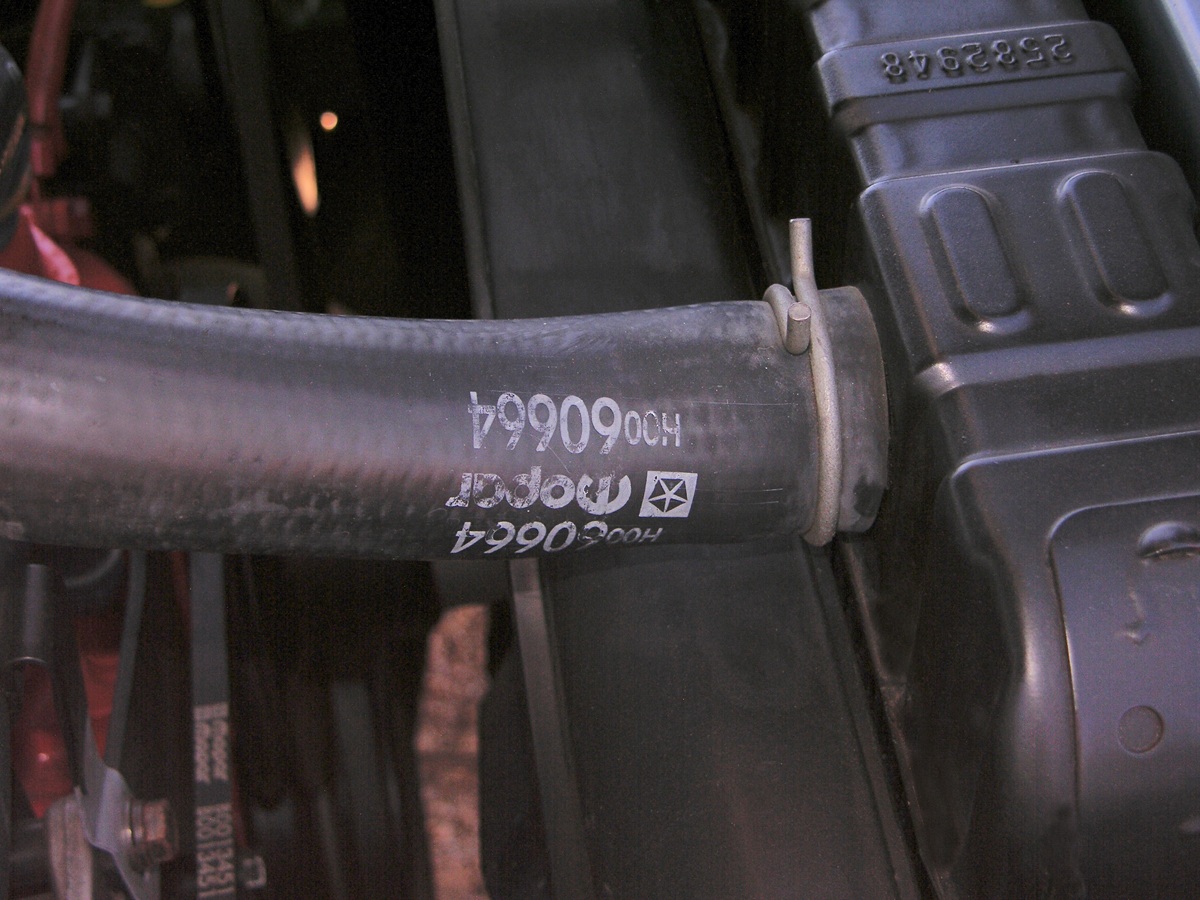

In keeping everything “original” in appearance, the original spring clamps used on the replacement “Mopar®” radiator hoses.

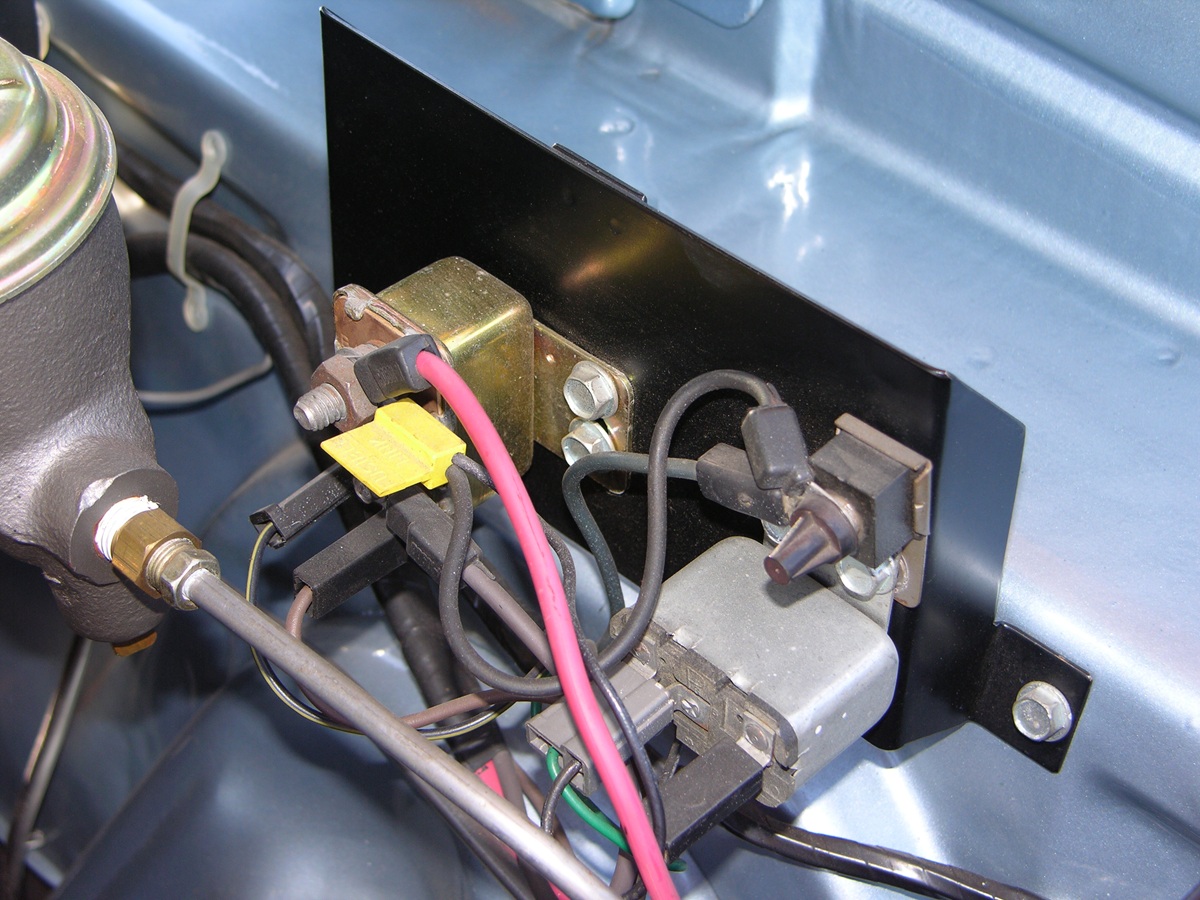

Unique to 1966 Street HEMI engine-powered cars, the driver’s side inner fender has a bracket that attaches the twin relays (starter, horn) and it was engineered as a result of the larger HEMI cylinder heads that prevented the firewall-mounted starter relay as normally fitted. This was a one-year-only location of the relays.

DOG DISH

As delivered from the factory, this car came with body color wheels and the standard hub caps, with 7.75×14 “Bluestreak” (4-ply nylon) tires. 426 HEMI emblems appeared on the lower front fenders so to warn any stoplight street rivals!

The pictured “B4” Medium Light Blue Metallic Belvedere II convertible is considered one of the “rarest of the rare” HEMI engine-powered cars ever built. In this case, only a handful of 1966 Plymouth HEMI ragtops were produced. Ten such Street HEMI Belvedere II convertibles – six automatics and four 4-speeds, were produced. This one came from Kelley Chrysler-Plymouth (Marietta, Georgia) and was built at the St. Louis final assembly plant, with a scheduled build date of June 14, 1966.

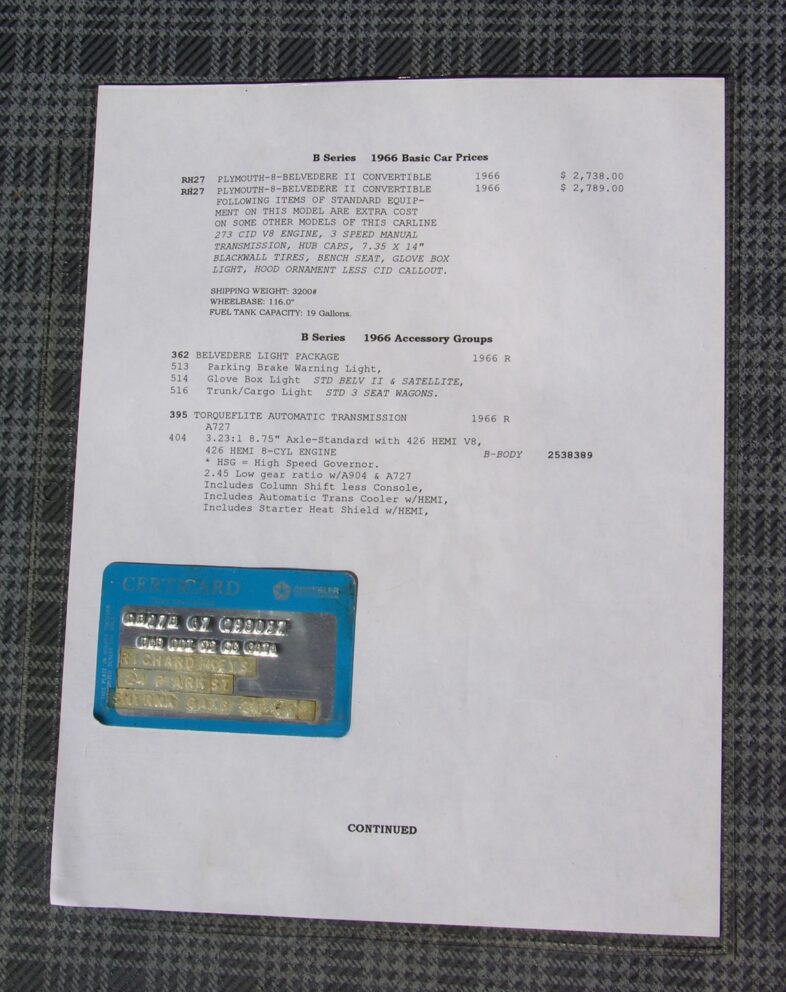

FULLY DOCUMENTED

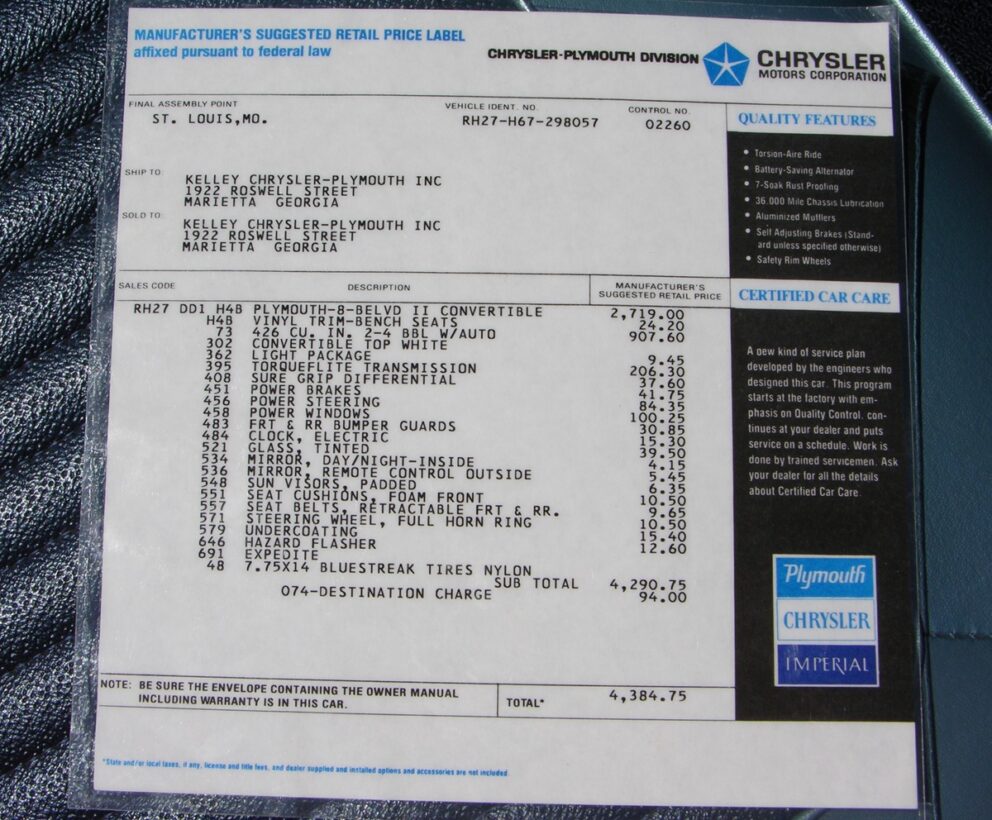

This car (VIN # RH27-H67-298057) is authentic in every way, even included the original “Certicard” issued to original owner for dealer service/warranty work, plus window sticker which lists the total price and options.

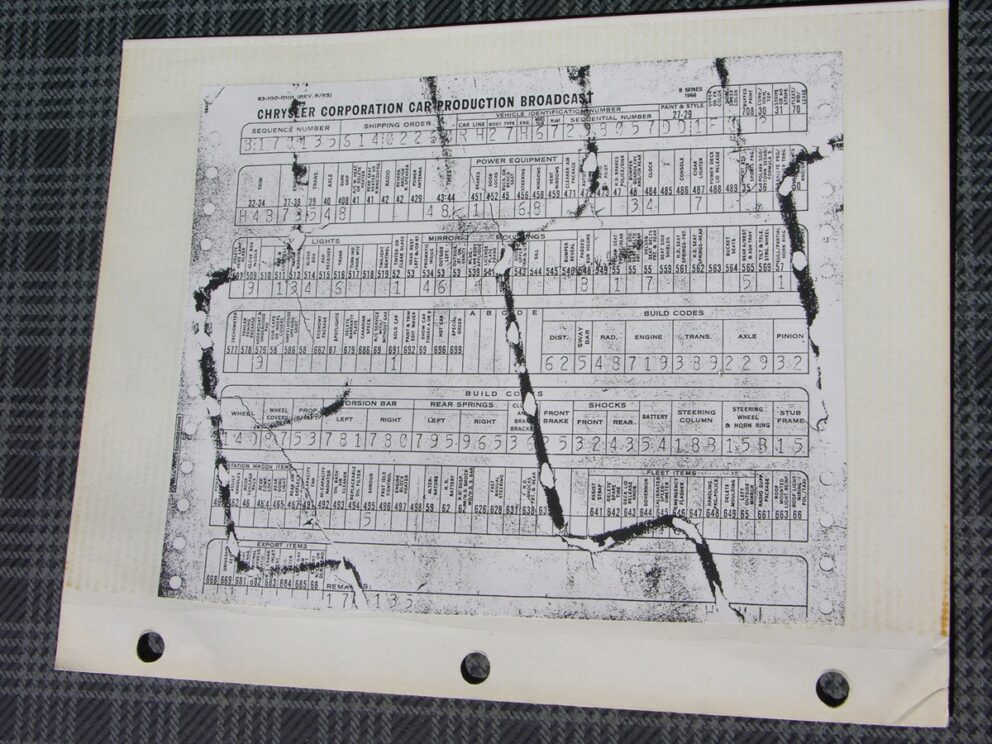

The fender tag shows the “RH27” which signifies 2-door convertible. Copy of the Broadcast Sheet (found inside the rear seat springs) shows the “H” code for engine, factory code for 426 HEMI. Also shown marked “8″ for power windows,”4″ for the dashboard mounted clock.

PAPERWORK

The owner had collected a variety of supporting paperwork for the rare Mopar car, including back-in-the-day advertisements and pages from the Plymouth brochure.

STREET HEMI VISUALS

Visually, the easy way to distinguish the outside appearance of the Street HEMI engine from the previous 1964-65 race HEMI engines is the use of the inline twin Carter carburetors. Note: non-clutch fans (four-blade, steel) were used on 1966-67 Street HEMI manual transmission applications, six-blade aluminum fans with viscous clutch used on 1966-67 Street HEMI engine-powered automatics.

NHRA DRAG RACE COMBINATION

For this first year of the new Street HEMI engine from Chrysler Corporation, the best combination for those who drag raced was the “RL21” Belvedere I 2-door sedan, equipped with the Street HEMI engine, 4-speed manual transmission and Sure-Grip differential. It was the base, no-frills, lightest weight B-body car that could be ordered. By being a “no radio” car, it was the best way to keep the overall weight down as much as possible.

This is the combination that Jere Stahl and Bill Stiles chose to compete in the NHRA A/Stock class, of which proved to be a very potent performer. After scraping the undercoating off (as delivered by Plymouth, of which provided the car as a sponsorship), they were able to get the car’s weight to a minimum, plus whatever else that done in preparation! “The first thing we did was to take the engine apart and blueprint it,” stated Stahl when the car was highlighted in the magazines at the time. The rotating parts were balanced and Mopar step-seal pistons and rings were fitted (legal within the rules) and also legal in the stock class was the switch to a Racer Brown STX-23 camshaft and lifters. Other mods included the use of a S/S transistorized distributor (from the 1965 race engine) and a pair of Stahl “Total-Tuned” headers. Champion N64Y spark plugs were used.

The result? It ran as quick as 11.33 seconds in the 1/4-mile. Very impressive considering the rules mandated 7-inch grooved “cheater” slicks (M&H 9.20-15 were the chosen brand) which were inflated between 12 to 14 pounds of air. To achieve best traction with these narrow slicks, two or three burnouts were done prior to staging the car up to the starting line. With the Top Stock wins at the NHRA Springnationals, the US Nationals and the World Finals in Tulsa, the immaculately prepared sedan was the dominant car in the category. “The best part of the whole deal is that we didn’t have to do anything to the car from week-to-week, except change the plugs,” recapped Stahl after the spectacular 1966 racing season. “It just seemed to run and run, no matter what.”

Author: James Maxwell

0 Comments