This 1968 Dodge Charger is an Enthusiast’s Engineering Marvel

If you attended 2024 Roadkill Nights Powered by Dodge and perused the Cruise-In area, you likely saw a great many old and new Chargers, but there was one that stood out from the crowd – the car named “Red Bull”, owned and built by Steve Calabro. At first glance, you see a classic Dodge Charger with a considerable amount of custom body work, including generously flared front and rear wheel openings and a custom front fascia that replaced the factory bumper, but as you look into this car more, it just keeps getting more extreme and more unique.

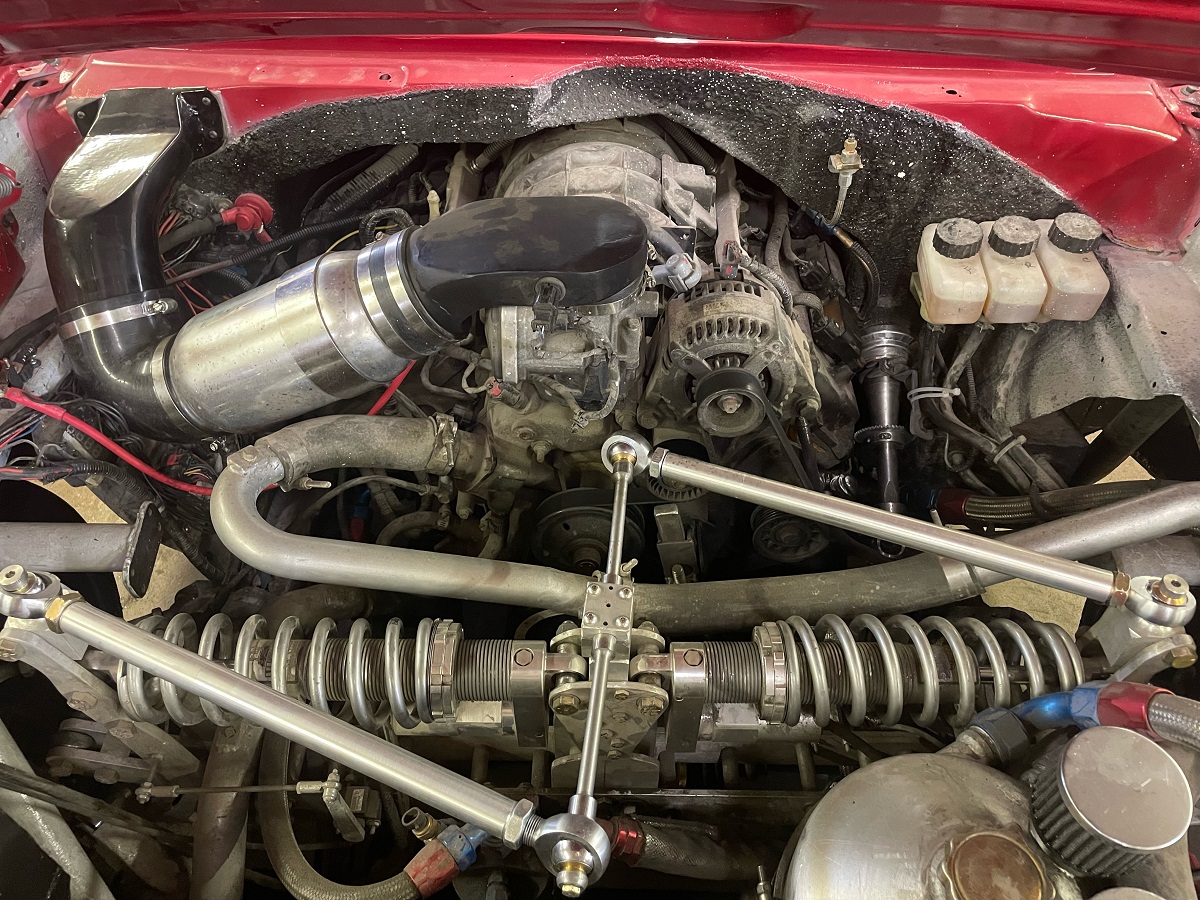

The first indicators that this is more than just a classic Dodge Charger with custom body work are the large AWD badges on the fenders and, yes, this car really does have all-wheel-drive. It also has a modern 5.7-liter HEMI® engine mated to a Tremec T-56 manual transmission, but he didn’t just swap in a modern engine – he moved the engine back to improve front-rear weight balance and to make room for the AWD parts. Only the front-most two cylinders are ahead of the original firewall locations, well behind the front wheels, making this a mid-engine car. He also re-engineered that entire suspension setup, creating a one-off inboard pushrod similar to what is used on the world’s highest performance supercars.

Making this build all that much more amazing is that all of the work was done by Steve Calabro – the custom metalwork on the body, the engineering and design of the inboard suspension setup, the entire all-wheel-drive system – and he has absolutely no automotive technical training of any kind. The only step of the process with which he has had significant help was painting the car. He started with the bare chassis of a 1968 Dodge Charger and done every bit of planning, engineering and labor to create the engineering marvel that you see here, with some of the work done in a temporary tent-garage with a dirt floor and much of the work done in an average two-car residential garage.

When Steve Calabro acquired his 1968 Dodge Charger, it was almost a bare chassis. Someone else had started the project of completely restoring this classic Mopar® muscle car and about halfway through, they decided to sell the car. Calabro bought the rolling chassis and a whole lot of parts with the intention of using all of the bits and pieces to build a car, even though he didn’t have any automotive technical training or experience of any kind. Based on the VIN, it was a factory 383 two-barrel car, but his plan at first was to build a mild 440 that would make this Charger a nice cruiser.

However, one night while Steve was playing Forza Motorsport, he had a unique idea for his Dodge Charger. On that video game, you can change engines and even change the drivetrain configuration, so when using a classic Charger on the game, you can install a modern HEMI engine and all-wheel-drive. The all-wheel-drive system gives the cars on the game a significant traction advantage and he thought that it would be cool to have that same advantage with his classic Dodge.

Around 2009, Steve Calabro began building his 1968 Dodge Charger. Over the course of the next 15 years, he has built that rolling chassis into one of the most unique classic Chargers I have ever seen. During that period, he spent years teaching himself how to weld and do bodywork, he spent years researching and learning about all-wheel-drive systems to figure out which option would work best for this project and he spent years re-engineering the entire suspension system – incorporating modern supercar chassis technology into a classic Mopar … and he has done this all without any sort of training or prior experience.

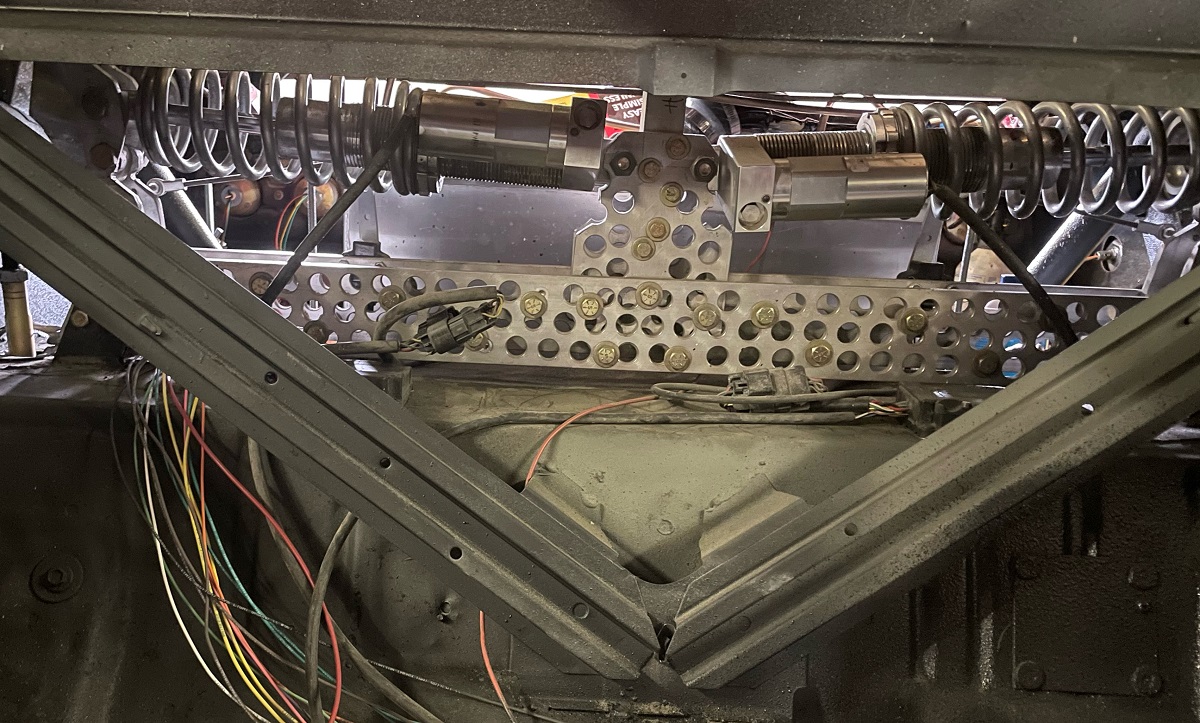

Steve Calabro has chronicled his 15-year build on a variety of websites, including pretty much every painstaking detail over the years. In speaking with him, he explained just a few of the biggest hurdles along the way. For instance, the custom widebody design is crafted completely from hand-formed and welded steel, but Calabro started out trying to make the panels with fiberglass until he found that metal would give him the look that he wanted. In the end, the custom body panels took about two years to create. When designing an all-wheel-drive system, he worked with multiple different front axle assemblies before landing on the unit from a Trailblazer SS. Due to space limitations under the Charger, he had to relocate the transfer case from the driver’s side of the engine bay to the passenger side, and he has to install it upside down. Of course, installing it on the opposite side of the car and upside down required all sorts of custom parts, from half shafts to mounting components, but he made it work. Of course, there was significant amounts of re-engineering when he installed the inboard pushrod suspension, as that not only changes the components behind the wheels, but he also had to make space for the coilovers to be horizontally mounted in front of the engine and just behind the rear seat brace – and he had to make sure that there was proper clearance for all of the additional moving parts of this inboard system.

There is so much going on with this build that it is hard to touch on all of the unique aspects, but when looking the car over at Roadkill Nights, I noticed the custom vents behind the rear glass and another huge vent between the taillights. I figured that the vents had something to do with cooling for the brakes and rear differential, but they are actually aerodynamic improvements. Calabro found that the area behind the rear glass and the area under the rear end of the car both collect air and negatively impact the aerodynamic properties. The vents by the rear window vent down into the wheel wells to relieve the air captured behind the rear roofline and the vent between the taillights prevents air from getting trapped up under the rear end of the car at speed. Those two areas show the lengths that Steve Calabro has gone to with this car to make improvements everywhere he can.

The best way to make sure to mention everything that is done to this 1968 Dodge Charger is to just list it all out.

Engine:

2009 5.7-liter “Eagle” HEMI V8

Cowl induction air intake

Auto Verdi dry sump oil system

180-degree headers ARP head studs

Transmission:

Custom-built Tremec T-56 6-speed manual transmission

Triple/double done synchronizers

Billet aluminum flywheel

McLeod 10.95 clutch

Front Drive:

Chevrolet Trailblazer SS front axle

4.56 gears

Custom 3-piece driveshaft

Custom RCV Performance CV shafts

C6 Corvette steering knuckles

Rear Drive:

Speedway Engineering Mod Lite Floater

Quick Performance aluminum thru-bolted 3rd member

Detroit TruTrac differential

4.56 gears

Transfer Case:

NV-149 mounted upside down

Custom 32-spline input shaft

1.5-wide chain

All cryogenically treated internal parts

Suspension:

Vi-King Berserker ASM computer-controlled suspension system

Custom SLA front control arms

3-link with Watts link rear suspension

Custom Woodward manual steering rack

Bat Wing sway bars

Push rod actuated coilover shocks mounted inboard front and rear

Brakes:

14-inch front rotors under Wilwood 6-piston calipers

12-inch rear rotors under Wilwood 4-piston calipers

Tilton triple master cylinder pedal assembly with remote bias adjustment

Wilwood master cylinder with remote reservoirs

Aston Martin electric parking brake calipers with a custom controller

Exterior:

1968 Dodge Charger body

1969 Dodge Charger 500 grille

Custom steel widebody treatment including the front fascia

Lotus Fire Red paint

Dapper Lighting 5.75 headlights

Digi-Tails LED taillights

18×10.5 Koenig Neoform wheels wrapped in 315/30 Falken Azenis RT615K+ rubber

Interior:

Dodge Challenger front bucket seats

Custom rear seat

10-point roll cage

AIM MXG Strada digital dash

NuRelics power windows

Sitting at Roadkill Nights with the darkened windows closed, this 1968 Dodge Charger might look like it is finished, but Calabro explained that the last big step of this project is the interior. As you can see in the picture showing the rear suspension, there are still loose wires running through the cabin, but he plans to tackle the interior this winter. For now, he has a running, driving 1968 Dodge Challenger that has been re-imagined and re-engineered in just about every way by an enthusiast who did all of the work himself.

While Calabro did the vast majority of work himself, there were a few people who were instrumental in this unique build coming together. He thanks Paul at RCV Performance for making the custom front CV shafts. He thanks his cousin, Joe, for spraying the paint and clear coat. He thanks Ben at Street Rod Designs for the design, rendering and bull graphics. Most importantly, he thanks his wife, Ariel (who was his girlfriend when this build began), for “putting up with this build as long as it’s been going on”.

0 Comments